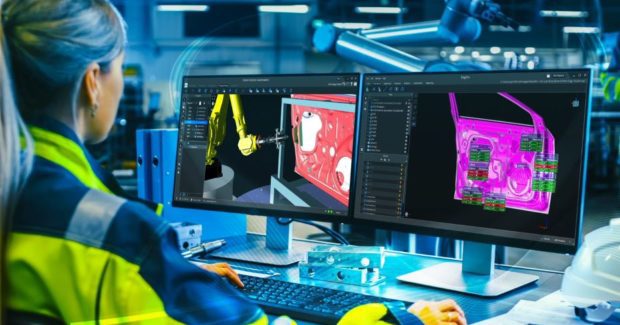

Hexagon Unveils Platform to Accelerate Autonomous Quality Assurance for Industry 4.0

Hexagon’s Manufacturing Intelligence (North Kingstown, RI) has unveiled HxGN Robotic Automation, providing robotic programming and control software that enables non-specialist quality professionals to program industrial robots to perform fully automated quality inspection.

Posted: September 30, 2021

HxGN Robotic Automation enables manufacturers to accelerate adoption of Industry 4.0 by intelligently devising optimal inspection routines in a single step. According to Hexagon, that task that would typically demand significant time and attention from both a metrology and robotics professional. With HxGN Robotic Automation, manufacturers can now develop the program offline, away from the production line in a digital reality, and deploy the program to the robotic cell. The software is already used by market leaders such as ŠKODA AUTO to enhance its manufacturing production lines.

“We have reduced the time required to program robotic inspection from several days to just four hours using the new software, so we can be ready and waiting to inspect a new vehicle as soon as we want to begin production,” said Martin Jehlička, chief of measurement center at ŠKODA AUTO. “Robotic automation and Hexagon’s high-speed laser scanning systems have already halved the inspection time for parts and sub-assemblies, and installing these automated inspection cells on the production line is fundamental to our Industry 4.0 strategy of making data available and actionable so quality trends can be identified quickly or, in some cases, automatically corrected.”

According to Hexagon, the software is built on open design principles, interfaces with new or existing industrial robots, and is flexible so that quality professionals can employ the most appropriate metrology sensors to help rapidly future-proof factories with real-time, inline metrology. Hexagon added that by enabling real-time measurement data to be automatically captured at source and used to optimize production in real-time, the technology embeds quality assurance in the heart of production to enable faster, self-correcting manufacturing and free up staff time for other tasks, such as data analysis.

“Automating inspection is vital to enable OEMs to consolidate quality across increasingly diverse, complex products and processes,” said Stephen Graham, president of metrology and production software at Hexagon’s Manufacturing Intelligence division. “Truly smart manufacturing needs swift, accurate, and accessible measurement data, but many robotic inspection systems are costly, complex, closed systems that are incompatible with manufacturer’s chosen tools and inaccessible to non-specialists. HxGN Robotic Automation is built around openness so that manufacturers can swiftly and seamlessly future-proof entire manufacturing lines for robotic inspection.”

HxGN Robotic Automation supports Hexagon laser trackers, Leica T-Scan and AS1 scanners and directly interfaces with FANUC and KUKA robots, while built-in postprocessors enable the robot controller to work with a range of third-party robots. Future versions will support the HxGN SLS Structured Light Scanner and third-party sensors.

Hexagon provides sensor, software, and autonomous solutions.