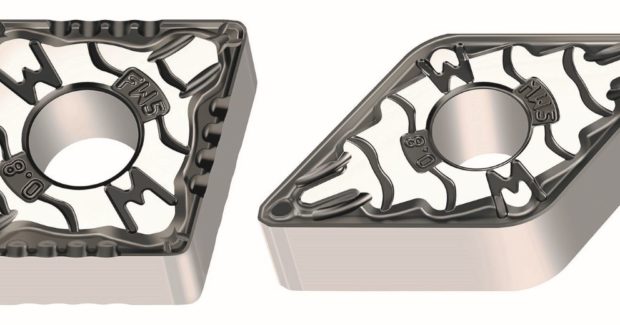

Walter’s New Wiper Geometries Boost Feed Rates While Maintaining Consistent Surface Finish

FW5 and MW5, Walter’s new universal wiper geometries, deliver consistently high-quality surfaces through the life of the tool.

Posted: August 10, 2021

Walter USA LLC (Waukesha, WI) has unveiled the next generation in universal wiper geometries with its FW5 and MW5. These new geometries deliver consistently good surface finish throughout the life of the tool, reducing machining time and increasing productivity. FW5 and MW5 wiper geometries for turning and facing, with circumference-sintered indexable inserts, generate reduced cutting pressure, enabling their use on thin shafts and for internal machining.

The FW5 geometries have a new wiper curved cutting edge and V chip formation for short chips. The FW5 can also be used on components with long overhangs thanks to the reduced cutting pressure. The MW5, with its longer cutting edge, is suitable for the highest feeds.

The FW5 and MW5 are available on a variety of inserts. These new Walter geometries reduce machining time by increasing the feed by up to 300 percent while maintaining surface quality and can allow users to combine roughing and finishing operations using the same insert.