Robot Ready, Environmentally Friendly Non-Aqueous Modular System Uses Recycled CO2 for Surface Prep

Air and Liquid Systems, Inc.’s Rochester Hills (MI) non-aqueous cleaning and surface prep removes contaminants from plastic, composite, metal and glass. It uses a fraction of the energy, material, and labor costs than conventional cleaning methods.

Posted: August 15, 2021

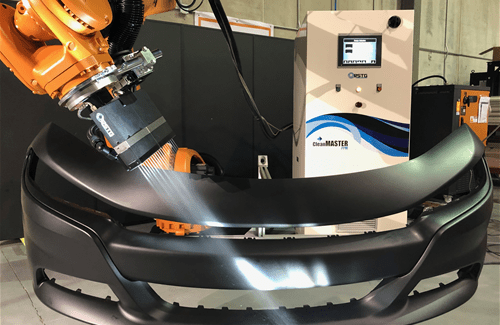

Robot ready, environmentally friendly, and widely accepted, the modular system uses recycled CO2 for non-aqueous cleaning and surface preparation before painting and bonding. This dry alternative to aqueous cleaning offers favorable energy savings and yield gains in lieu of mechanical washing and tack-wipe methods. Air and Liquid Systems will be in Booth D45057.

The system removes defect causing contaminants, such as fibers, particles, light oil and grease, consuming minimal energy with low CO2 consumption. Production ready, it runs reliably with a three-to-six-month simple maintenance interval at a fraction of the floor space of aqueous cleaning systems.

CO2 cleaning heads are designed for the automotive spray paint industry to provide a 5-foot-to-10-foot-wide cleaning path effectively cleaning at speeds to 1,000 mm/s to match paint cycle times. The cleaning heads mount statically or robotically to follow part geometry coupled with engineered hose management for clean routing and exceptional 6th axis articulation.

Air and Liquid Systems is a vertically integrated manufacturer of engineered systems for process air filtration and purification, process liquid filtration and purification, high purity water generation through reverse osmosis, process discharge water recovery and reuse through physical/chemical treatment and ultrafiltration, parts coating pre-treatment cleaning systems including CO2 cleaning, custom blow-off and drying systems, emission controls, energy saving and energy recovery systems, paint process and coating systems design, automation and implementation. We offer process analysis and diagnostic evaluations toward process improvements related to building and process temperature/humidity controls, air balance, curing, oil and solids separation challenges. We are an authorized FANUC systems integrator supporting our cleaning systems and paint finishing systems integration activities.