Reduce Scrapping. Reduce Downtime. Weld More!

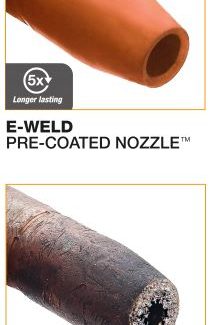

Industry leader Walter Surface Technologies (Windsor, CT) has formulated an innovative and cost-effective solution to nozzle spatter build-up with its new E-WELD PRE-COATED NOZZLES™.

Posted: August 12, 2021

These are longer-lasting welding nozzles that reduce downtime spent scraping out spatter and slag or even replacing the nozzle. By ensuring free flowing shielding gas, the wire is heated evenly, helping you achieve your goals while minimizing downtime and welding operation costs. These game-changing pre-coated nozzles also eliminate the need for flammable spray-on coatings. They provide a safe solution to nozzle spatter build-up, helping you increase your productivity and reduce consumable expenses.

The formation of spatter is a time-consuming challenge frequently faced by welders. In MIG welding, spatter not only adheres to your work piece, but also clogs your MIG gun’s nozzle. This spatter buildup obstructs your nozzle’s shielding gas flow, which causes uneven heating of the wire and results in poor quality welds. This also requires constant nozzle cleaning or changeover. Not only does this slow down productivity, but also drives up the costs of your consumables.

The E-WELD PRE-COATED NOZZLES are made of high-quality copper with a unique ceramic coating on both the interior and exterior surface that prevents spatter from adhering to the nozzle. This prevents nozzle obstruction, allowing shielding gas to flow freely for higher quality welds. The highly concentrated ceramic coating is also highly durable for long-lasting protection against thermal damage. This also provides these nozzles with a life span up to five times longer than standard OEM nozzles. These truly provide a cost-effective way to keep up production, achieve high-quality welds and reduce nozzle changeover.

“It took over two years of research and prototype iterations to refine this unique ceramic solution and create an application process that offers exceptional durability to our welding nozzles,” stated Walter R&D Product Manager-Welding Solutions, Philip Laforest. “I am proud to bring to the market a product that embodies the spirit of Walter Surface Technologies by helping our customers work better and safer.”

The E-WELD PRE-COATED NOZZLES are available in various sizes and models compatible with Miller®, Lincoln® and Tregaskiss® welding equipment.

Come visit Walter Surface Technologies at FABTECH at booth B35060 in the welding pavilion to learn more about the new nozzles and discover our full line of metalworking solutions.