Online Bonus Coverage: Siemens’ Vivek Furtado Discusses Digital Twins

The September issue of Fabricating & Metalworking features a cover story entitled: “Seeing Double, How Smart Factories Use Digital Twins.” F&M Editor Rachel Duran visited with Vivek Furtado, head of machine tool digitalization for Siemens, about digital twins and Industry 4.0. Furtado provided a compelling discussion regarding the digitization of machine shops.

Posted: August 18, 2021

Web Exclusive

By Rachel Duran

Rachel Duran: There are several different ideas of digital twins. Detail Siemens’ approach to digital twins.

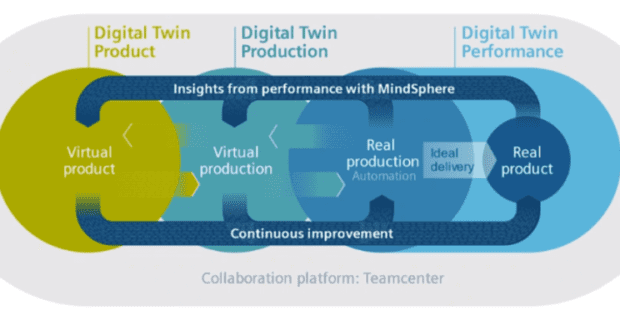

Vivek Furtado: The Siemens approach, we have three types:

- Digital twin of the production, which is basically the whole factory. And when I say factory, this would include all capital equipment and manufacturing assets.

- Digital twin of the product, the actual product you are producing.

- And then you have something called the digital twin of performance, which is basically more of the relevant processes and optimizing in the machining or the overall factory processes.

RD: How do factories get the most out of their expensive machines?

VF: Let me start by saying our approach is two-fold. On one hand, we address the machine builders themselves with the digital twin solution.

The typical process of designing a machine is you would follow a sequence, which is to make the mechanical design, then you would make the electrical design, then the software and the PLC design, and at the end you would have a machine and you go to the end customer and say, ‘okay, this is what you asked for.’ We have a feedback loop.

What we can provide today, especially with our SINUMERIK ONE for end users and machine builders, which comes to the controller hardware as well as a native digital twin, we call it Create MyVirtual Machine, is that without touching a nut or a screw you can actually build the whole digital twin with all the engineering technologies and include steps like the mechanical, the software process, all in one model.

Siemens Named as a Global Industrial IoT Platform Leader by IDC MarketScape

[No. 1] That means on one hand it really enhances the productivity of the engineering process because you can do simultaneous engineering, you don’t have to do them sequentially any longer. This dramatically reduces time-to-market and staying ahead of the competition.

Number two, because you have not really done anything physical yet, you can run several iteration groups within the engineering process, also with your customer. For example, with a tool change. Is this the way you want your tools to be changed? There are things that often come up in the commissioning phase, where you might suddenly realize that you are going to have a collision with the part during a tool change.

So instead of having to rebuild the machine, the changes can be incorporated in the virtual model thus minimizing costs and resources and keeping the customer satisfied.

Now coming to the end user: The benefit an end user would have before committing to a capital investment is to actually test the machining of parts intended to be manufactured using the digital twin. The digital twin of the product is already state-of-the-art as most CNC parts are designed over CAD/CAM.

The end user can load that part on the virtual machine and run, check the cycle times, surface quality and optimize the production in terms of tooling and program strategies, depending on the specific requirement.

So, within the end-user processes, there is a lot of production optimization that can be tried out before buying the machine. For example, part cycle time evaluation and accurate ROI calculations are especially relevant for expensive machines with a high machine hourly rate.

RD: Do you find yourself working with more medium sized or small-sized companies; what is the average? How can small companies benefit?

VF: Currently, from both the machine builders and the end-user perspective, it is more the larger customers we find ourselves working with — customers who have more than 50 to 100 machines. They would go for the fully holistic digital twin I just talked about.

But there are also possibilities to start in a smaller way. Users should not have the perception that you really have to invest a lot and go in for a full-scale digital twin. There are several steps you can take to get there without having to invest a lot of capital.

RD: Please provide an example of your services in action and how you were able to assist a manufacturing company in achieving success with digital twins.

VF: A fairly large automotive manufacturer from Detroit has been very excited with the solution. As you know in the automotive industry, every second or even millisecond counts because it is all about cycle time. The customer uses our solution to optimize their cycle time, not only over the entire machine line, but also optimizing individual machines.

This is based on the fact that our solution can accurately predict the cycle time of the parts manufactured because [of] how our digital twin works. It is not an emulation; it is a simulation of the controller. We call it the VNCK [virtual NC kernel], which is essentially the control kernel integrated into the simulation environment — in this case with NX CAD/CAM.

What we can also do is upload the real archives of the existing machine into the simulation model so the end customer can accurately predict and thereby optimize the entire line using real production data.

So even going beyond individual machine simulation, this automotive customer is implementing a whole line simulation where all the transfer of products, the parts between the machines, are also being simulated, thus improving productivity and possibly saving on further capex investments.

RD: What are some of the latest trends when it comes to digital twins; and where to next?

VF: Well, we now have the controller, the toolpath — everything can be simulated and you can see the whole machine.

But I see more coming in terms of complete motors and drives integration — where you have a complete mechatronics model included in the machine, and even with more simulation. Additionally, connected to that, we will see the process called force simulation, which is not only a geometric simulation, also it calculates mechanical forces within the simulation model. That way, for example, you can’t load your spindle this much, before actually building the machine. This way, you can test the limits on the virtual model more than on the real machine.

RD: What message do you want readers to take away from a discussion on the digitalization of machine shops?

VF: The digital twin itself brings along a lot of use cases. I mentioned some use cases around process optimization. Other use cases include: validating a part program, training, simple job preparation. This can be done, and in fact is being done today, also without a complete digital twin.

My message?

Just get started… there are products… we have a very economical product called SinuTrain, for example, that also has integrated simulation in it where you can upload part of your machine capabilities into that model. This will get people started on their road to digitalization. That way, they can save valuable resources by training new people on a new machine, which prevents you from having a lot of machine downtime.

You can get started with a free copy of SinuTrain. The fully functional software costs about $2,400. That is something I would suggest to help machine tool users get started on their digital journey.

RD: For machine shops, the technology can be overwhelming; it is not familiar to them. What types of skills do they need, or workers do they need, or is it just get in there and do it with the team you have?

VF: I see there is some change in mindset when you talk about IoT, where applications are cloud- or subscription-based. Things are opening up; people are becoming more open to trying it especially as the prices are more attractive compared to perpetual or on-site licenses.

There is also the question of generation gaps. People who are in their 50s and 60s might be more reluctant to trying it compared to the generation in their 20s and 30s who have grown up with a smartphone and are already familiar with this kind of technology.

What I want to say is that you don’t have to be an IT or technical expert you simply have to understand how to use it.

I think it sounds sometimes overwhelming, but it really isn’t. I think people can get started working on digital twins in just a matter of weeks. If you start small, take the step-by-step approach, it is definitely doable, and even for the 50s or 60s generation, I wouldn’t see any problem.

Learn more about digital twins.