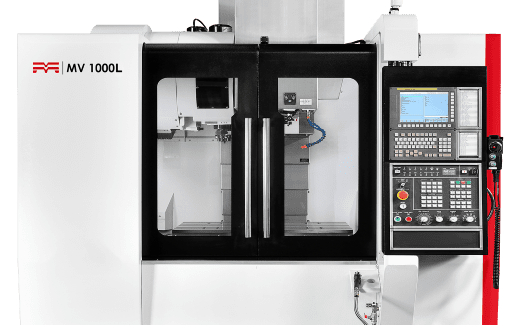

Methods Machine Tools Brings High-End Features to Conventional Class of CNC Machines

From Methods Machine Tools Inc. (Sudbury, MA), the latest addition to the company’s machines is the vertical machine tool MV-1000L, a three-axis CNC machine with many high-quality components and features.

Posted: August 20, 2021

According to Methods, the MV-1000L is well ahead of the basic industry standards with high-end features, such as 19 hand-scraped surfaces, alpha-series FANUC motors, and a BIG-PLUS dual-contact spindle.

“The MV-1000L’s sturdy construction and premium components put it in a league of its own,” said Nick St. Cyr, Methods Machining Center product manager. “Weighing in at 15,432 pounds, the MV-1000L is a heavyweight contender designed to knockout the most demanding machining challenges, giving users a high-end machine at an economical price.”

Powered by 20 horsepower and 12,000 rotations per minute (RPM) 40-taper spindle, the machine tool is well-suited to tackle many jobs in a shop. Whether it’s roughing an engine block or finishing a medical implant, the MV-1000L provides the needed rigidity, speed, and reliability.

Other attributes of the machine tool include a FANUC 0i-MF Plus control with 200 block look-head and two megabytes of part program storage, macro B, remote manual pulse generator (MPG) for easier control and increased ease of use, and a comprehensive thermal compensation system.

The MV-1000L is the latest addition to our growing line of Methods machining centers. Developed by Methods, the machine tool was manufactured by Litz Hitech Corp. Each machine is backed by Methods’ service and support. All Methods machining centers are engineered to precise standards, fully inspected to meet strict quality and design specifications, and comply with ISO/ASME standards. Additionally, the product line is the only brand of machining centers manufactured by a Taiwanese company with FANUC controls.