Lenzkes Clamping Tools: Quality Through Consistency and Innovative Developments

Booth D46761 Lenzkes Clamping Tools Inc. (Christiansburg, VA) was founded in 1976 in Germany with the goal of improving productivity and reducing setup times in manufacturing.

Posted: August 14, 2021

Now, with more than 45 years of experience and locations in Germany, Switzerland, France, Spain, Great Britain, Poland, China and the USA, and more than 100,000 satisfied customers worldwide, Lenzkes Clamping Tools belongs to the leading manufacturers of clamping tools and is known for its high-quality workholding solutions. With a vast variety of unique tooling available, we can fit your company with a product that will be beneficial for your company’s individual needs.

Lenzkes S 10/20 clamping frames, and the further development, Lenzkes S 30/40 — now S33/45 clamping frames were launched as the first product line. Today, after 40 years on the market, clamping frames are still in high demand for metal forming, machine shops and pressure die casting.

Features of the S Series Clamping Frames:

- Clamping frames made of hardened alloy steel, drop forged

- Stepless vertically adjustable (S10/20 and S33/45)

- Horizontally adjustable due to the unique grooved frame design (S33/45)

- Non protruding bolts (S20 and S45)

- High clamping forces as low as 2,600 lb.-force up to 15,700 lb.-force

Listening to customers and reacting to their requirements always leads to new product developments and product improvements. Lenzkes Multi-Quick release tools were designed to combine features to meet customer requirements and are our most demanded tools.

Features of the Multi-Quick Series:

- Wide variety of Multi-Quick tools in different styles are available, always designed for respective applications

- Stepless horizontally and vertically adjustable

- Strong clamping pressure for small clamping torque

- Quick setup equals time savings

- Protection plates available to protect surface while clamping a workpiece

- Clamping forces as low as 4,450 lb.-force up to 22,480 lb.-force

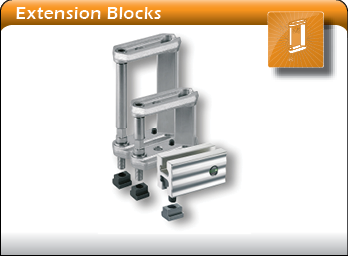

To provide a suitable solution for clamping larger pieces, molds or dies, Lenzkes’ Extension Blocks B50 or A58 offer extended clamping heights.

Features of Extension Blocks:

- Extension Blocks B50:

- Made from extra strong aluminum alloy and a perfect addition to MQ-Series clamps as well as to Clamping Frames S10/20 and S33/45

- Holding force up to 13,480 lb.-force

- Extension Blocks A58:

- Made from hardened alloy steel with connecting elements drop forged and tempered steel

- Versatile addition to the MQ-Series clamps

- Holding force up to 17,980 lb.-force

Because workholding fixtures for low profile workpieces and free surface machining are in demand Lenzkes developed and designed NU10, FL10, SK10 and SKQ10 side clamps offering solutions for different workpiece sizes.

Features of Side Clamps:

- Side clamps NU10 and FL10 made of hardened alloy steel

- Side clamps SK10 and SKQ10 made of drop forged alloy steel and available in different styles

- NU10, FL10 and SK10 side clamps can be used and moved parallel to the t-slot

- SKQ10 side clamps can be used and moved parallel and at any angle to the t-slot

- Clamping forces as low as 450 lb.-force for the smallest side clamp style, and up to 14,600 lb.-force for the largest side clamp

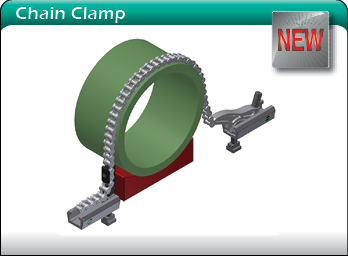

Lenzkes Chain Clamps were designed to provide the easiest, fastest and safest way to hold round and unconventional workpieces securely in place.

Features of Chain Clamps:

- To be applied as a workholding fixture for cylindrical workpieces, valve bodies, pump housings or pistons, etc.

- High clamping forces achieved via low torque requirements

- High chain adjustability due to innovative chain holder

- Easy installation and easy adjustment through stepless adjustable MQ-Clamps

- Clamping force up to 13,480 lb.-force