Felsomat USA Cuts Production Time and Improves Part Quality with Fully Automated Laser Welding Line

Felsomat created two laser welders for an automotive supplier in Mexico to cut production time and improve part quality in the supplier’s rear drive assembly and power transfer unit assembly.

Posted: August 25, 2021

“We’re thrilled that we had the opportunity to show this automotive supply leader the capabilities of our laser welding line and that the customer saw the incredible benefits of our system,” said Daniel Maerklin, president at Felsomat USA. Maerklin continued, “We knew our complete laser welding system would be the perfect fit for the application because of its production quality, versality, and short cycle times. Clearly, the customer saw the benefits too as we just shipped their second complete system.”

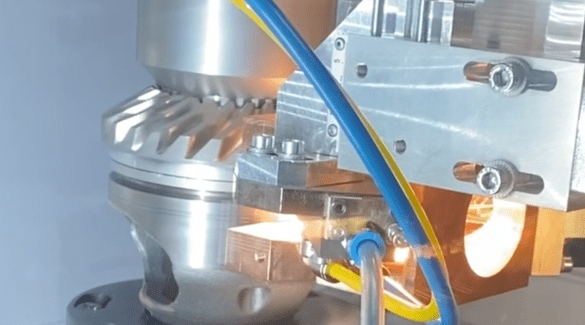

The Felsomat laser welding cell is a complete welding system. “We wanted the laser welding system to really do it all, essentially be a one-stop-shop for the laser welding of parts,” Maerklin said. “With this system, we’ve successfully achieved that goal.” The system includes press, laser clean, and ultrasonic test stations, as well as a robot handling system. By combining these pieces, the system can perform part assembly completely, minimizing production times and improving overall part quality.

Also, the laser welding line is versatile, with an interchangeable laser head and clamp that can be easily swapped for each individual part. “We know that the thought of changing out these pieces can be scary, but we’ve designed the machine so that it is not only simple to change but can also be done in no time,” Maerklin said. “We know that production time is critical, so we ensure changeover times are minimized.”

Felsomat’s laser welder is equipped with a 6 kW TRUMPF laser source. “We work very closely with the experts at TRUMPF and are excited to partner with them again for the laser sources in our state-of-the-art laser welders,” Maerklin said, adding that “to ensure parts are perfect, every time, our Felsomat laser welder is equipped with a laser seam tracking and weld monitoring system from Lessmueller.”

Want to See Felsomat Technologies In Person?

If you’re interested in seeing Felsomat technologies live, the company is hosting an open house at its headquarters in Konigsbach-Stein, Germany. The open house is Oct. 12 – 14. An automation company, Felsomat GmbH & Co. KG will showcase its e-motor traction motor stator and rotor assembly systems. This includes a fully functioning stator line that will run real parts for an Italian customer that produces German sports cars, as well as e-motor trickling station demonstrations, a 2D and 3D hairpin stator bending demonstration, and FHC hobbing and machine demonstrations. To register, visit www.felsomatinnovationday.com.

Not Able to Make it to Germany?

If you can’t make it out to Germany, you can see Felsomat technologies by visiting Felsomat USA Inc. The U.S. operation will host an Oktoberfest celebration at its facility in Schaumburg, IL. The event will be held Oct. 28, 2021. During the event, the company will showcase its latest technology, automation systems, and hobbing machines. To register, visit www.felsomatinnovationday.com.