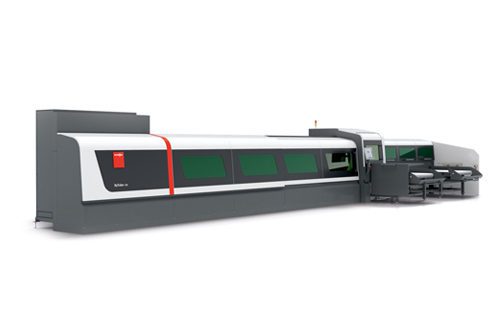

Bystronic Offers New Laser Cutting System for Tube Processing

Bystronic Laser AG (Niederönz, Switzerland) has introduced the ByTube 130, a new laser cutting system that offers fabricators and manufacturers an easy entry into tube processing, a growing manufacturing market with a bright future.

Posted: August 22, 2021

In the past, many metal processing job shops and original equipment manufacturers limited their operations to the processing of sheet metal. In doing so, they missed out on sales opportunities. With the new ByTube 130 laser cutting system, job shops can now gain access to new customer groups. Tubes can be applied in variety of fields: from the automotive and construction industries to furniture, machine, and equipment manufacturers. Exploiting this market potential is critical to success in the metal processing business.

According to Bystronic, the ByTube 130 is the optimal solution for sheet metal processing companies that want to expand their capabilities. An estimated 85 percent of the market potential lies in the small tube segment, so the ByTube 130 is geared toward the processing of tubes with diameters between 3/8″ and 5″ and workpiece lengths up to 28′. The machine has a loading capacity of 11 lbs. per ft. An estimated 90 percent of the market is 2D cutting, so the ByTube 130’s 2D cutting head can process a large number of customer orders.

Fiber Laser Ensures Speed and Flexibility

The ability to process a wide range of material types and thicknesses offers users the flexibility required to manage a diverse range of orders. Additionally, the ByTube 130 has the potential to substitute complex and cost-demanding processing steps: A growing number of fabricators and manufacturers are discovering laser cutting as an alternative to the two processes of sawing and drilling. The fiber laser performs both processes simultaneously — and faster. Also, deburring is minimized thanks to clean-cutting edges. So, labor costs are reduced. Higher throughput speeds also reduce the cost per part, which constitutes a huge advantage in the competition for the best price.

Software Turns Beginners into Pros

State-of-the-art sheet metal processing is not possible without high-performance software. The powerful Bystronic ByVision Tube user interface is highly intuitive. All the functions relating to tube laser cutting are displayed on a single, 22″ HD touchscreen. Users can visualize realistic 3D part animations, create cutting plans, and monitor production processes with easy-to-operate, software-driven menu selections. Even entry-level users without extensive experience can immediately operate the ByTube 130. Cutting jobs are set up quickly. Whether small series or large orders, with ByVision Tube, users move from the incoming order to the delivery of the finished parts in a quick and efficient workflow.