The “Smart Factory Five” for Robotic Automation

There are key areas manufacturers must be mindful of when creating a completely integrated smart factory, especially where robotic automation is concerned.

Posted: July 7, 2021

ADVANCING AUTOMATION

BY MATTHEW HARTSHORN

From small, specialized plants to million-square-foot factories, production facilities are getting smarter, transforming into fully connected yet flexible environments that cultivate greater productivity. Seeing the long-term value for their operations, manufacturers are taking the digital transformation leap, implementing a host of advanced tools including robots, digital sensors and machine monitoring platforms to address rapidly evolving business demands.

As a result, the manufacturing sector is expected to be the largest integrator of Industry 4.0 inspired technologies during the next five years1, making it imperative for manufacturers to be mindful of five key areas when creating a completely integrated smart factory.

NETWORKING

To connect and enable a myriad of unique devices into any production environment (new or old), a strong wired and wireless network infrastructure is critical. From equipment integration and communication to complete system control and diagnostic data delivery, industrial networks can help maintain application functionality for greater efficiency and accuracy.

Establishing this type of factory setting can be extremely challenging for IT staff, so it is important for company leaders to have a clear vision and plan for device implementation before the process begins. Likewise, it is advantageous to remember that the most successful industrial networks allow the flexibility to add, remove and relocate equipment throughout the factory, as needed.

When dealing with automation communication platforms, there are many options to consider. Common examples include AS-Interface, CC-Link and Modbus/TCP. Growing steadily in use, easy-to-use industrial Ethernet is a newer option that now represents 64% of the global industrial market share for newly installed nodes2. The utilization of this type of industrial network typically eases device integration and increases safety due to the reduction of robot control wiring required.

CYBERSECURITY

While having all devices on a network has its upsides where data collection and remote access are concerned, the interconnectedness of this equipment can put manufacturers at greater risk for cyber-attacks. Hacking and viruses are all too common in today’s industrial landscape, and often result in production stoppage, data loss, data theft or even device failure.

To avoid these extremely costly outcomes, company leaders should take a security-first approach and weigh the various options available. While some manufacturers may choose to keep devices off the internet completely, others may choose network isolation via a Virtual Private Network (VPN) that requires some level of authentication, or even Multi-Factor Authentication (MFA). Organizations such as research institutes or manufacturers with protected intellectual properties may choose to implement an adaptive firewall using artificial intelligence (AI) that can detect and defend a robot against external connections. No matter the method, constant monitoring of an industrial network by IT staff is paramount, and any vulnerability must be addressed or patched as quickly as possible to maintain security and safety.

DEVICE CONNECTIVITY

Perhaps the most daunting part about a smart factory is the ability to connect the multitude of different devices required for smooth operation. Most factory equipment comes with its own set of tools and protocols for data transfer, historically making it a complex endeavor to get all devices “talking” in sync. Thanks to standardization efforts of network protocols, the communication between devices in the industrial environment is improving.

Ease of use and the ability to adapt to the ever-changing landscape of the manufacturing sector are imperative to the success of systems integrating with the Industrial Internet of Things (IIoT) world. Systems like these may utilize protocols like the OPC-UA (Open Platform Communication Unified Architecture) interface to connect heterogeneous systems across an extended enterprise for sharing data. State-of-the-art platforms such as Phoenix Contact’s PLCnext Technology combine IEC61131-1 programming, modern programming languages, safety hardware/software and control system security to help future-proof industrial automation ecosystems.

DATA HARVESTING

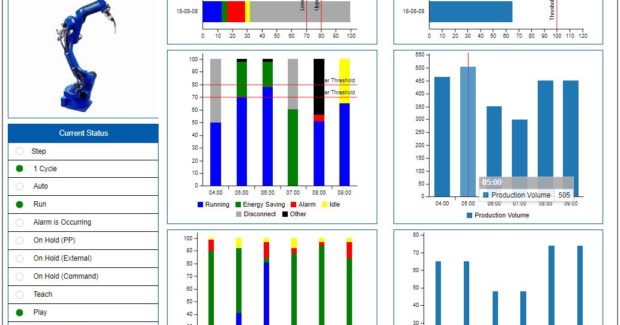

Connected devices, including robots and their peripherals (scanners, welders, grippers, etc.), can provide a wealth of information pertaining to equipment performance and operational trends. Manufacturers would be wise to learn how to transform this data into usable information. In this regard, factory automation monitoring systems that are extensible (capable of supporting multiple brand devices via add-on functions) and can collect all operational data in real time are proving to be highly beneficial.

Edge Server systems, like Yaskawa Cockpit, that use a leading OPC-UA interface enable an integrated, intelligent and innovative approach that allows manufacturers to see what is happening at any point on the value creation chain to gain actionable insights for informed decisions. Along with the ability to better manage manufacturing and supply chain complexity, company leaders can now harness meaningful data from Yaskawa robots plus other brand devices for descriptive, predictive, prescriptive and cross-analytics, establishing customized operations that can better fulfill company goals.

DIGITAL SKILLS

The shocking truth for many manufacturers today is that for smart factories with robotic automation to reach their full potential it requires a skilled human component. Industry 4.0 has caused a technological shift, and the primary capabilities needed to fulfill many industrial tasks are changing as a result. Moreover, as digitization and automation continue to permeate the industrial landscape, there will continue to be a dichotomy between existing worker skill sets and the knowledge necessary to operate robotic systems and other advanced technologies.

To push forward into Manufacturing 5.0, where the human touch and smart technology work in harmony to function at peak performance, manufacturers should be proactive and create a talent pipeline more in line with the skills required for future success. Most likely, this will entail company leaders to invest in their current workforce by providing adequate industrial education opportunities, as well as incentivizing motivated employees to learn the necessary skills for challenging positions.

LET THE DIGITAL TRANSFORMATION BEGIN!

While smart factory implementation is easiest when a facility is being built, most manufacturers will face a different reality, transforming current operations while trying to keep up with stringent customer demands. The path to success will look different for every company and may be peppered with growing pains but partnering with a knowledgeable robot OEM or integrator can help. From hardware and software options to factory workflow planning, seeking expert advice is an ideal place to start.

References

- 5 Predictions for Smart Factories in 2021, Thomas Insights, 2021

- Industrial Network Market Shares 2020, HMS, 2021