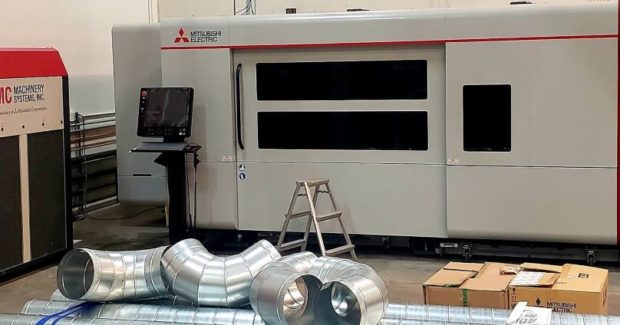

Lasernut Installs New Mitsubishi GX-F Advanced Fiber Laser

MC Machinery Systems Inc. (Elk Grove Village, IL) recently installed a new GX-F Advanced Series artificial intelligence-enabled fiber laser at Lasernut (Norco, CA).

Posted: July 17, 2021

“I had never been sold on fiber lasers because of micro-burr and concerns about edge quality,” Waggoner said, “but the GX-F has burr reduction technology that makes burr non-existent.”

The GX-F Advanced Series also has Mitsubishi gas-reduction technology, which allows the laser to deliver more power while using up to 77 percent less nitrogen. According to Waggoner, this technology is already saving significant money. “The GX-F Advanced pays for itself in the energy savings alone,” he added. “When you look at the numbers, it’s a no-brainer. It’s an unreal machine, just an amazing piece of equipment.”

Waggoner said the reduced operating cost, along with faster production and higher capacity, is translating into increased profitability: “It’s already made a measurable impact on our business.”

Before the GX-F was installed in early June, Lasernut was backlogged and was even turning away jobs. Within two weeks of installation, the new laser was operating at full capacity, the backlog was eliminated, and lead times were reduced, Waggoner said. He added that operators needed very little training because AI does so much of the work and the smartphone-like control panel is easy to use.

Other key features of the GX-F Advanced Series include:

- AI-assisted cutting that optimizes cutting performance

- Augmented reality with drop and cut, part rotation, and rectangular nesting

- Real-time tracking of electric and assist gas consumption

- Real-time on-site and remote monitoring of the cutting process

- Remote diagnostics and predictive maintenance

- An automated nozzle changer that supports continuous processing

Waggoner said that the timeline from purchasing the new laser to delivery and installation was only a few weeks and that the laser was up and running much faster than expected. “The laser was running production parts within five days from delivery, which is insane,” he said. “MC Machinery did everything they promised and more.”