High Levels of Accuracy at Lightspeed

CMMs provide precise measurements and shorter measurement times.

Posted: July 8, 2021

Today’s coordinate measuring machines (CMMs) offer speed, precision and versatility. They come in the offerings such as horizontal arms and cantilevers, or structural light 3D scanners, also called optical measuring machines. The entire surface of a component is scanned, creating a digital twin of a physical component. Advances in non-contact optical measurement, which are often portable, allow your operators to do more. Software integrated into CMMs creates automatic data analysis that can be shared throughout your facilities. Read on to learn about some of the latest options in the category.

NEW GENERATION CMM OFFERS VERSATILITY, ACCURACY AND PRECISION

Mitutoyo America Corp. (Aurora, IL), has added the CRYSTA-Apex V Series to its product line of coordinate measuring machines. This new generation of CRYSTA-Apex Series offers high speed, accuracy, precision and versatility to the Mitutoyo CNC coordinate measuring machine line up.

Key features include:

- High-Speed/High Acceleration/Drive: Features a maximum measuring speed significantly faster than competitive CNCs. The combination of high speed and high acceleration dramatically reduces measuring time and cost.

- Shorter Measurement Times: Users can set measuring paths for high-speed scanning, 3D and active scanning of complex workpieces.

- Temperature Compensation System: Guarantees measurement accuracy for temperature conditions between 16 degrees to 26 degrees Celsius. Independent sensors work in tandem to measure scale, workpiece and ambient temperature. Results are superior to comparable systems that only compensate for scale temperature.

- Smart Factory Functionality: The CRYSTA-Apex V series utilizes three smart factory applications, consolidating the information management manufacturing process within a network:

- Status Monitor: Allows remote monitoring of the operational status of measuring instruments.

- Condition Monitor: Enables remote monitoring of the current condition of measuring instruments.

- MeasurLink: Reduces the production of defective parts through “visualizing quality” via complete data management.

- Smart Measuring System: Allows on-line monitoring of the measuring status and visualization of measurement data, enabling product quality improvement and internet of things capabilities.

- Superior Flexibility: The CRYSTA-Apex V Series can adapt to work on a range of sizes for small- to medium-sized work pieces. It also features multi-sensor capabilities and compatible vision and scanning probe technologies.

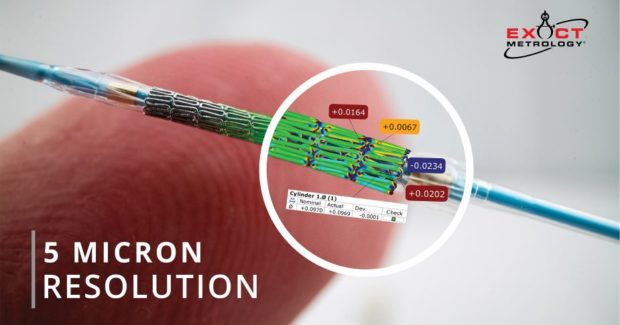

EXACT METROLOGY INSTALLS ZEISS METROTOM 6 SCOUT SCANNER

Exact Metrology, a comprehensive 3D metrology service provider and hardware sales company, has installed a ZEISS METROTOM 6 scout scanner, formally known as a GOM CT, at its facility in Brookfield, Wis.

The METROTOM 6 scout, a powerhouse of resolution for CT inspection and metrology, digitizes complex parts including the internal geometries at the finest level of detail. Users obtain a complete 3D image for GD&T analysis or nominal-actual comparisons. The metrology CT excels in digitizing small plastic parts.

To showcase the ability of Exact Metrology’s CT scanning services, powered by the METROTOM 6 scout, a scan was done on a medical stent. This medical stent, with a diameter of only 1 millimeter, was measured within a 5-micron resolution. Exact Metrology’s inspectors were able to evaluate critical features with amazing precision.

CT scanning provides several benefits including being the only way to get 3D views inside a part and the only way to obtain accurate dimensional data without cutting up and destroying an object. CT scanning takes little time to capture data and troubleshoot parts, and offers multiple uses with one scan (void analysis, inspection, volume, porosity, reverse engineering, etc.) Exact Metrology is ISO, AS9100 Certified as well as FFL and ITAR Registered.

ZEISS TO ACQUIRE CAPTURE 3D INC. EXTENDING ITS EXPERTISE IN 3D MEASUREMENT AND INSPECTION SOLUTIONS

Zeiss plans to expand its national coverage in the United States for its Industrial Quality & Research division by acquiring Capture 3D. Headquartered in Santa Ana, Calif., Capture 3D is the leading U.S. partner for GOM 3D non-contact measuring solutions. “We are pleased to bring the Capture 3D team and their know-how into the Zeiss Group,” stated Dr. Jochen Peter, a member of the Zeiss Group Executive Board responsible for the Industrial Quality & Research division. “After the acquisition of GOM two years ago, we will now also combine our strategic forces in the important U.S. market to provide customers with best-in-class measuring solutions from one source.”

“We look forward to being a part of Zeiss to combine our efforts in serving our customers with the best in class measuring solutions and services,” added Richard White, CEO of Capture 3D. “Being part of the Zeiss Family will open up new opportunities for the Capture 3D team and our customers in the future.” Capture 3D will become part of the Industrial Quality Solutions strategic business unit within the Zeiss Industrial Quality & Research division.

Capture 3D Inc.’s products include the GOM ScanCobot. By combining a fully automated robotic arm with the ATOS Core coordinate measuring machine, the GOM ScanCobot works as an automation upgrade for ATOS Core users or as an entry point to automated systems. The machine is mounted on a portable workspace with a rotating table for ease of use. Its metrology-grade non-contact blue light technology, which captures millions of points per quick scan.

www.capture3d.com and www.zeiss.com

CMM INNOVATOR LAUNCHES FIVE ULTRA-ACCURACY PORTABLE MEASURING ARMS

LK Metrology (Castle Donington, England) has expanded its FREEDOM arm range of 3D articulating arm metrology systems, or portable measuring arms, with the launch of five ultra-accuracy models in both 6-axis and 7-axis variants. The FREEDOM ULTIMATE and FREEDOM ULTIMATE SCAN arms are available with measurement volumes from 2.5 to 4.5 meters, based on model. Each complements the comparable size of existing FREEDOM CLASSIC and higher accuracy FREEDOM SELECT products with six axes designed for touch probing, as well as the 7-axis SCAN equivalents for multi-sensor metrology including laser scanning. The products offer increased precision in applications, ranging from quality control and on-machine verification to reverse engineering, virtual assembly design and 3D modelling. Measuring accuracy is enhanced by up to 8% in comparison with the next most precise products in the range, SELECT, while compared with the entry-level CLASSIC arms the improvement is up to 43%.

OPTICAL CMM MACHINE MEASURES TIGHT TOLERANCES

Bruker Alicona’s (Itasca, IL) µCMM, is the first purely optical CMM machine, and measures extremely tight tolerances in high accuracy. The machine combines the advantages from tactile coordinate measuring technology and optical surface measuring technology to measure the dimension, position, shape and roughness of components with only one sensor. This optical CMM produces high geometric accuracy of several optical 3D measurements in relation to each other. This results in the measurement of small surface details on large components as well as precisely determining the position of these individual measurements in relation to each other. The optical CMM measures surfaces such as common industrial materials and composites. Operators use single-button solutions, automation and ergonomic control elements such as a specially designed controller. Air-bearing axes with linear drive enable wear-free use and highly accurate, fast measurements.