Tooling Manufacturer Adds Third Lucifer Furnace

A Connecticut-based manufacturer has installed a Lucifer 7GT-H19 for heat treating in a nitrogen-based atmosphere. The energy-efficient unit heats to 2100 F and is regulated by a Honeywell digital controller.

Posted: April 15, 2021

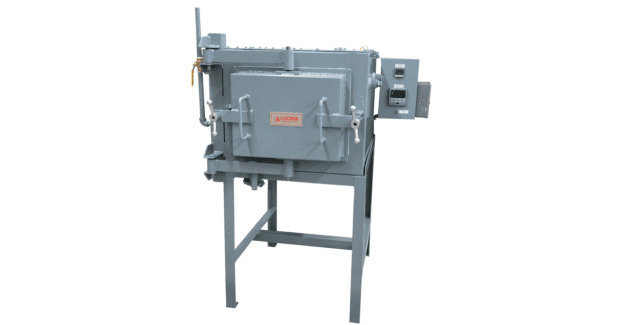

Southwick & Meister Inc. (Meriden, CT), has added a third Lucifer GT box furnace to its production capabilities. A manufacturer of premium-quality collets, bushings, cutting tools, and more, Southwick & Meister uses Lucifer’s furnaces to heat treat products with a nitrogen atmosphere.

The most recently purchased Model 7GT-H18 is fabricated from 10 gauge sheet steel reinforced with structural steel members continuously welded to form a solid shell for operation with a positive flow of inert atmosphere.

The 9-inch-high by 12-inch-wide by 8-inch-long chamber is lined with 5 inches of combined lightweight firebrick hotface backed with coldface mineral wool for energy efficient operation and low outside shell temperature.

Powered with 9.5 KW and heating to 2100 degrees (F), the furnace heats by heavy-gauge coiled wire elements supported in high-temperature, cast monolithic holders that are easily replaced. A 1-inch thick cast hearth plate protects floor brick and supports the work load. Temperature is regulated with a Honeywell DC2500 digital controller.

Add-on features include an Overtemperature Safety System for unattended operation and a seven-day timer.

Noting Lucifer’s well-built products and strong customer support, a Southwick & Meister spokesperson said, “It’s been a great relationship for many years.”