Simulation Software Optimizes Press Productivity

Tooling Tech Group can analyze incoming part files, fix clash and clearance violations, identify tool design changes, and make adjustments to achieve the highest strokes per minute (SPM) without going through trial and error on the stamping floor. This applies to servo, mechanical and hydraulic presses regardless of manufacturer.

Posted: April 5, 2021

Tooling Tech Group (TTG) (Macomb, MI) is a single-source supplier for the metal forming industry, offering everything from die design, simulation and engineering through die build, repair, tryout and production stampings.

The company has experience in the design and build of dies in materials including HSLA 980, dual-phase and trip steels. In addition to its state-of-the-art CAD software, TTG employs laser technologies in its design process, helping to quickly assess and correct any spring-back conditions in the early stages of development. This enables the company to tackle very complex parts and achieve dimensional accuracy in a very short timeline.

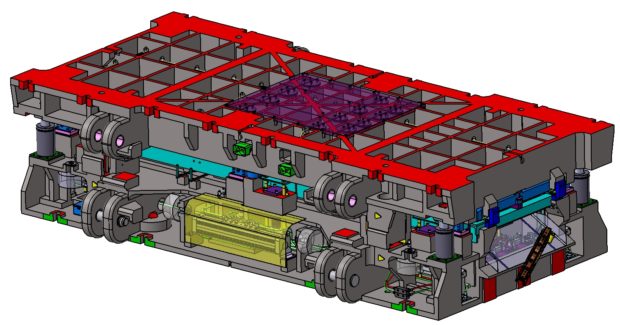

All dies are tried and tested in a production-intent environment including feed rates, sensors, and scrap shedding capabilities. The company has seven stamping presses ranging from 500 tons to 2,750 tons, with the larger presses equipped with drop-through bolsters that accommodate 72-inch-wide coil stock and thicknesses up to 5mm. All the presses feature tonnage monitors and sensors for pre-sample production runs. The equipment processes materials including CR steel, HR steel, galvanized, stainless, aluminum, and advanced high-strength steels (AHSS).

The company uses T-SIM Solutions (Rockford, MI) simulation software to optimize transfer press design. The software provides key insights into the die process by identifying crashes, clearance issues and inefficient transfer system curves before machining of the die, saving considerable time and money. TTG can also optimize existing tools to increase capacity in current press operations.

TTG can analyze incoming part files, fix clash and clearance violations, identify required tool design changes, and make adjustments to achieve the highest strokes per minute (SPM) without having to go through physical trial and error on the stamping floor. This applies to servo, mechanical and hydraulic presses regardless of manufacturer.