Grinding Method Eliminates Need for Multiple Machine Tools

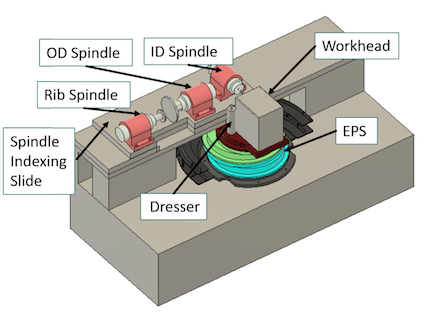

Almost any operation that requires a combination of high accuracy and high force can be improved with the Eccentric Positioning System (EPS) from Coventry Associates. The grinder uses three circular rotary tables on top of each other instead of linear slide systems.

Posted: April 7, 2021

The 3-axis Eccentric Positioning System (EPS) from Coventry Associates (Shrewsbury, MA) can position an object anywhere in an 215-mm circle with high accuracy, repeatability, speed and controlled force. The fully electric system eliminates hydraulics, vastly reduces setup and cycle time, uses less energy, and has a smaller footprint than existing approaches at a competitive price.

The company’s initial application is inside diameter (ID) grinding, but potential applications include all grinding and turning operations. Almost any operation that requires a combination of high accuracy and high force can be improved with EPS.

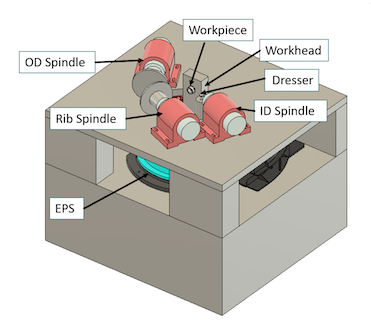

The EPS MultiTool, for example, combines the operations of an ID grinder, OD grinder and rib grinder into a single system. The workpiece and dresser are mounted on the EPS. Several spindles can be arranged about the workhead. This allows the controller to present the workpiece to each spindle in sequence with high accuracy, repeatability and speed. Only one load/unload cycle per workpiece is required.