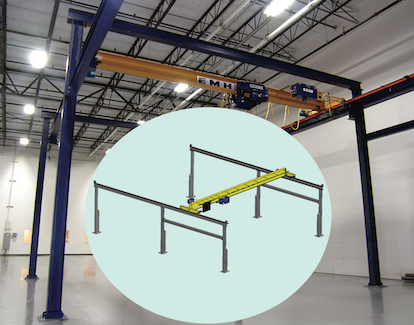

Wider, Taller Crane System Adapts Where It’s Needed

Engineered Material Handling’s NOMAD XW, the latest in its modular, freestanding line of bridge cranes, assembles easily with bolts and most can be installed without footers, thanks to practical design details. Choose from options to suit 1- to 4-cell manufacturing systems, as well as optional travel speeds, and battery or rechargeable radio controller.

Posted: March 2, 2021

NOMAD XW from Engineered Material Handling (EMH, Valley City, OH) expands on the NOMAD Freestanding Crane line and extends its capabilities with overall widths up to 60 feet, overall heights up to 25 feet, and capacities from 2 tons up to 20 tons.

EMH’s Modular NOMAD Cranes provide flexible solutions for manufacturers when needs change, or when a traditional overhead crane installation is either difficult or impractical. Their base plate design allows most NOMAD systems to be installed without footers – the cranes are also designed for bolted assembly, so they’re easily dismantled, relocated and reassembled as needed.

NOMAD Cranes are available for one- to four-cell manufacturing systems, with safety-enclosed-type runway electrification brackets welded on runway beams and conductor bars installed in the field.

Shipped complete with mounting plates as well as bolts and bumpers, the systems are available in top running end-truck travel speeds of 80 or 120 FPM (VFD). Wire rope hoists provide lifting speeds of 16/2.6 FPM with trolley speeds of 65 FPM (VFD). Bridge conductor cables are pre-wired to quick disconnect plugs.

NOMAD Crane Solutions come standard with radio control and include a hand-held AAA-operated radio controller. Rechargeable models are optional, as is a back-up pushbutton station.