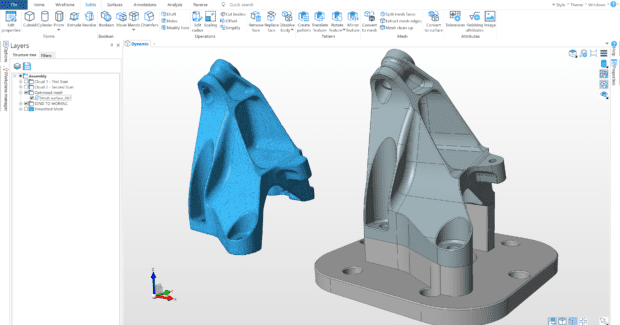

Reverse Engineering Software Provides Digital Twin That’s Ready for Manufacturing

Designed from the ground up from metrology scan to manufacturable model, REcreate software from Hexagon Manufacturing Intelligence aims to uncomplicate the reverse engineering digital workflow by reconciling incompatible data types and technologies.

Posted: March 12, 2021

Despite the availability of highly capable metrology systems, reverse engineering processes can require complex digital workflows to account for incompatible data types and technologies. This impedes productivity and can introduce errors. Furthermore, those workflows require significant experience and access to multiple tools that can create bottlenecks. REcreate software from Hexagon Manufacturing Intelligence (Novi, MI) streamlines these workflows.

The program provides a single working environment from scan to manufacturable CAD model. The user can prepare CAD models and drawings from any point cloud data. Its fully featured CAD tool suite enables users to create complete and manufacturable CAD models as well as 2D engineering drawings. Analysis tools also enable manufacturing professionals to interrogate those 3D models and validate whether they are manufacturable before exporting as CAD or STL for computer aided manufacturing (CAM) or additive manufacturing processes.

While designed to be interoperable and slot into a customer’s existing processes, the solution offers additional benefits to customers that use other Hexagon technologies. Factories that use Hexagon’s portable arms for inspection, for example, can reduce training needs by allowing any operator to read inspection data directly from the device to reverse engineer using a single solution.