An Electromagnetic Chuck for Virtually Any Application

An increasingly popular alternative to standard mechanical workholders, magnetic chucks lower setup time and provide access to all sides of a workpiece. They’re particularly helpful for holding circular workpieces during hard turning and free state grinding.

Posted: March 11, 2021

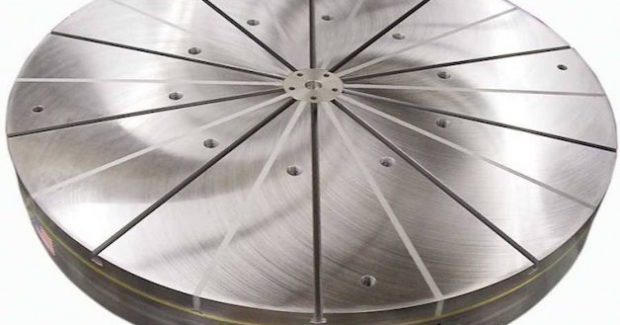

Rotary electromagnetic and electro-permanent chucks made in a radial-pole multicoil design for hard turning and free stat grinding is one of multiple product lines Industrial Magnetics Inc. (Boyne City, MI) has added to its mix with its acquisition of Walker Magnetics Group Inc. (Worcester, MA), North America’s oldest industrial magnet manufacturer.

Founded in 1896 by Oakley Walker, who invented the electromagnetic chuck, Walker Magnetics manufactures standard and custom electromagnetic, electro-permanent, and permanent magnetic chucks for use in grinding, machining, milling, turning, EDM, and molding applications. The company serves customers in 190 countries including steel mills, the rail industry, scrap processors, recycling centers, foundries, mining companies, machine shops, fabrication plants, shipyards, casting plants, machine tool distributors, automotive suppliers and steel service centers.

Rotary electromagnetic and electro-permanent chucks are made in radial-pole multicoil design to hold circular workpieces, such as rings and discs, when in hard turning and free state grinding. Most radial-pole chucks come with t-slots, but tapped holes are also available for mounting tooling. The smaller chucks four or six poles, while the larger chucks use 10 or 12 poles.