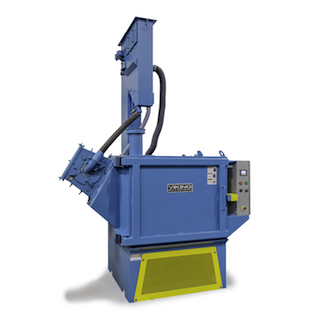

48-Inch-Diameter Table Blast System

Although Viking Blast & Wash System is primarily a custom manufacturer, the company gets enough requests for a 48-inch table blaster that the one-wheel machine’s a standard offering. Add a second wheel to completely blast an intricate part or lower cycle time.

Posted: March 4, 2021

The 48T shot blaster from Viking Blast & Wash Systems (Rose Hill, KS) gets its model number from its diameter capacity: 48 inches. Work height maximum is approximately 30 inches at the table’s middle (up to 34 inches at edge, pass 38 inches). The table is lined with a self-draining 3/8-inch-thick manganese alloy plate rotating at 5 rpm with a load capacity of 3,000 pounds. (Heavier weight capacities are available.)

The blast cabinet is constructed of 1/4-inch-thick AR 500 plate steel and reinforced with structural steel as needed. Cabinet is lined with ¼-inch-thick replaceable manganese plates in direct line with the stream. Full-opening AR 500 plate door provides access to the rotating table, and a catch tray contains abrasive to the cabinet upon opening. The door has a gasket to provide a positive seal during operation. Pneumatically controlled latch locks the door during the blast cycle. Removable safety screen protects the abrasive system from oversize contaminants.

Airless blast cleaning is accomplished with one Vmax 1500 15-horsepower, 3,600-rpm, 15-inch-diameter, eight-blade, center-fed wheel mounted directly to the shaft. (Two wheels are optional.) Lined with +1-inch-thick perimeter-cast chrome/moly wear plates, it’s thicker than other major brands. Wheel components are balanced and matched to ensure smooth operation. Blade tip is +10% thicker than other major brands.