Workholders Enhance Productivity for More Than CNC Machining

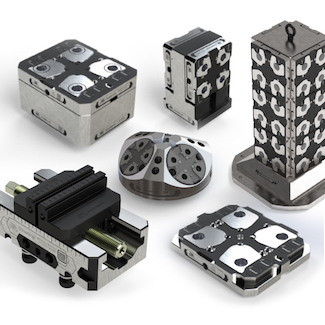

Comprising self-centering vises, quick-change bases and mounting accessories, Mate Precision Technologies’ 52/96 zero-point product line can be used for inspection, CMM, cleaning, washing, assembly, and additive manufacturing as well as on 3-, 4- and 5-axis machining centers.

Posted: February 12, 2021

The Mate 52/96 line of vises, bases, and mounting systems from Mate Precision Technologies (Minneapolis, MN) maximizes holding power in a compact, quick-change modular design that reduces setup time and process variability.

- DynoGrip self-centering vises feature maximum holding power in a compact system with minimal part movement and zero-point quality engagement with a four-post pull stud pattern.

- DynoLock quick-change bases provide zero-point quality engagement with a four-post stud pattern and best-in-class center accuracy and repeatability.

- DynoMount system includes tombstones, pyramids, risers, and dual right-angle mounts that feature zero-point quality engagement for four-point stud patterns.

The Mate 52/96 workholding system includes the company’s QuickSpecs product identification system, which allows real-time access to critical user data, CAD models and potential integration into business systems. The product also supports common robotic interfaces and palletizing systems to support factory automation.