We’re Closer Than Ever to First-Time-Right 3D Metal Printing

In its drive to develop an end-to-end solution for additive manufacturing, Siemens Digital Industries Software offers tools that simulate the printing process at various levels. To minimize the expensive quality-refinement process, modules identify and correct areas of malformation and shrinkage.

Posted: February 2, 2021

ADDITIVE MANUFACTURING COLUMN

BY ASHLEY ECKHOFF

Quality in manufacturing is never the result of a single action, but the accumulation of multiple actions all geared toward a quality output. For example, injection molding isn’t just about the quality of the mold; it’s also about the rate at which the material is injected, the temperature of the material during injection, the temperature of the mold itself, and the pressure at which the mold is held.

Additive manufacturing (AM) is no different. Everything from laser parameters and the firmware version on the machine all the way down to the tension of the screws on the building plate can affect print quality.

The goal of industrializing a manufacturing method is to quickly produce thousands of high-quality parts with minimal waste. However, fine-tuning an AM method to generate such results requires experience and knowledge of the variables that affect the process. Acquiring this knowledge requires manufacturing numerous iterations of a part to achieve quality output during production runs.

Perfecting a part this way is labor-intensive, resulting in wasted materials and time for each iteration and increasing the average cost per part. It keeps many metal manufacturers from adopting new technologies, but there are tools and procedures that help shorten or eliminate the quality-refinement process.

Addressing First-Article Print Quality

One way manufacturers address quality challenges is through specialization: To remove variables from development, a company limits its hardware and materials to a single or limited number of vendors, materials or processes.

This approach greatly expands employee knowledge of the tools and materials they’re using, but can hinder the company’s growth by limiting exposure to innovative technologies or materials. Employees become experts at the process, but the lessons learned through thousands of prints are often only applicable to the machines and materials the company uses.

All this hard-earned process knowledge is lost when customer want a new material that’s been developed or a vendor comes out with a new machine and a slightly upgraded process. Even a firmware update could threaten part quality by changing a machine’s behavior. When and if that happens, the time-consuming learning cycle must begin again to master these new variables and gain the knowledge needed to print quality parts.

The Promise of Process Simulation

What if that cycle could be short-circuited? What if the ability to print a quality part didn’t depend on knowledge a few individuals gained at great cost through failure after failure?

This is the promise of process simulation. If the printing process is simulated with sufficient precision, the automated process rapidly accrues knowledge rather than relying on expensive trial-and-error. This software-aided approach decouples the optimization knowledge amassed from multiple iterations from the printer’s capabilities. If a printer needs updating or a vendor switches machines, the process knowledge isn’t lost.

Simulation software functions as a link between design and manufacturing and as a virtual development environment. Often referred to as a digital twin, simulation enables designers to maximize the printer’s capabilities. Instead of physically printing a part, the production process is simulated at various levels — whether it’s the melt pool in a sintering-based technology or the printer’s toolpath – to uncover defects that could arise due to the design or printing process. The team can save valuable time and resources by fixing problems before committing to the print.

To make this workflow more intuitive, our Xcelerator portfolio’s NX software integrates the important metrics of a wide collection of print methodologies into the design. This allows designers to work within the known capabilities of the intended printer, minimizing rework while promoting faster time to production-volume manufacturing.

By working at various levels to simulate the printing process in detail, the software identifies and corrects areas of distortion, shrinkage and error. These innovations assist in observing the deposition process in a granular manner, using diverse techniques to help manufacturers come closer to the prospect of printing parts correctly the first time, helping to improve time to quality parts up to 50% in many cases.

Simulation software can even refine the printer’s abilities.

With our acquisition of Atlas 3D Inc. in November 2019, we introduced cloud-based software for direct metal laser sintering (DMLS) printers called AM Build Optimizer.

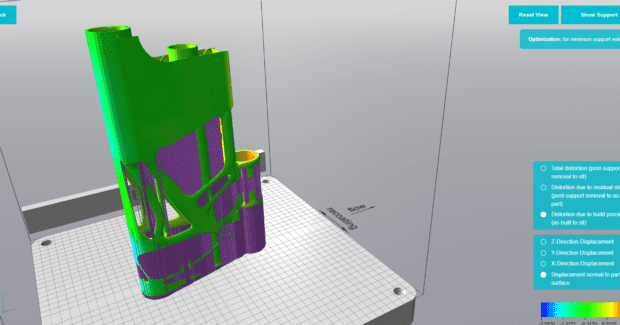

The program uses thermal distortion analysis to automatically provide the optimal print orientation and requisite support structures for a part in real-time. This allows the manufacturer—rather than the designer— to simulate the performance of over 100 build orientations in parallel. Combining AM Build Optimizer with the computer-aided engineering (CAE) additive manufacturing tools in Simcenter enables first-time-right 3D printing on an industrial scale.

We’ve also developed a way to assess fatigue performance by leveraging machine learning. Simcenter 3D Specialist Durability combines the power of experimental data and physics-based modelling to calculate how long a part will last based on key fatigue-influencing factors such as microstructure and porosity.

Finally, a solution under development called the AM Path Optimizer will identify areas of local overheating that can produce deformations. To alleviate points of concern and print the part consistently, the software will generate a corrected deposition path.

The Future: First-Time-Right Printing As The Norm

Achieving a higher return on investment is becoming necessary to compete in the additive manufacturing space, so there’s no overstating the benefits of resolving the challenges of high failure rates. Simulating the printing process is the best way to reduce the phyiscal iteration cycle required to achieve high-quality prints; and tools like AM Build Optimizer, Simcenter 3D AM and Path Optimizer bring the vision of a first-time-right printing closer to reality.