The Rise of Trochoidal Milling: More Accessible Than Ever

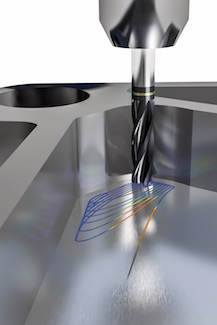

Circular machining with low radial engagement and constant feed per tooth extends tool life by minimizing heat and vibration when machining extremely hard materials. CAM and control developers are making it easier for any size shop to add this technique to their capabilities.

Posted: February 5, 2021

DEPTH OF CUT COLUMN

BY JOE PIZZOFERRATO

Imagine a satellite orbiting the earth at a constant height. If we applied enough force to bring it back to earth, the satellite would spiral downward. Each revolution produces a trochoidal movement.

This is the principle on which trochoidal milling is based. Think also of the 1960s-era Spirograph toy that produces colorful roulette curves. The user pinned to a piece of paper a plastic ring with gear teeth cut into the inner and outer diameters, then placed another smaller geared plastic ring on either side, inserted a ballpoint pen, and moved the smaller ring around the larger one. Like the pen in a Spirograph, the trochoidal toolpath is circular rather linear.

In the decade or so that trochoidal milling has been around, the industries we serve have seen positive impacts on tool longevity and 10% to 15% better metal removal rates (MRR) than conventional machining. Trochodial toolpath benefits include:

- Lower temperature at the cutting zone, which puts less thermal load on the tool. This improves process predictability and extends tool life.

- Uniform tool engagement both radially and axially. Using the entire flute length decreases cutting forces, which contributes to process stability by reducing vibration and load on the spindle bearings. It also keeps the tool sharper longer by uniformly wearing the cutting edges.

- Chips are thinner and these types of techniques provide superior chip removal, especially when using flood coolant or air blast. This reduces load on the tool and drastically reduces having to recut chips.

- Reduced tool deflection, which provides a closer-to-nominal stock allowance in all areas of the contour. The tool then removes the same amount of stock when finishing surfaces, which ensures more uniform surface quality.

A peel-type toolpath is similar and generates many of the same benefits. It produces a maximum of 10% tool engagement with a maximum Z depth and higher feedrates between the transition moves.

Both toolpaths have an arc-in path followed by a straight line or a line that follows the contour shape followed by an arc-out path. There‘s also a reduced feedrate upon entry for peel-type paths to maintain the appropriate relationship in feed per tooth between center of the cutter and the outside cutting edge upon engagement.

Applications Where Trochoidal Milling Excels

Because trochoidal milling minimizes heat and vibration, it’s well-suited for slotting; pocketing; roughing; and machining hard materials where chips are hard to break, such as titanium and Inconel. It’s also a great technique to be used in machining aerospace components and castings. Hardened tool steel and any material that‘s „work/case-hardened“ or abrasive can also benefit because they often exhibit chipping along the flutes.

Higher cutting parameters are also possible due to chip thickness principles. Chip thickness is exactly what it sounds like: the thickness of the chip the flute, or insert edge, creates. Chip thickness principles depend on the type of tool being used (90/45/10-degree cutting angle, for example) and whether the operators is peripheral or face milling.

If performing periphery milling or side milling for a peel-style operation with a standard flat endmill (90-degree edge), a coefficient can be applied that will increase the feed per tooth to maintain the same chip thickness as a conventional machining process. This coefficient depends on the ratio between ae (the working engagement) and D (cutter diameter).

Trochoidal Milling is Easier Than Ever

Thanks to ongoing improvements in machine motion control, computer-aided manufacturing (CAM) software and easy-to-use cycles available on many machine controls, trochoidal milling is becoming more accessible for shops of all sizes. It‘s definitely worth looking into for a long roughing routine or hard-to-machine materials.

Many software developers have been incorporating trochoidal-style roughing techniques. In DP Technology’s EspritCAM program, it’s called ProfitMilling; CNC Software’s Mastercam calls it dynamic milling; in Open Mind Technology’s hyperMILL, it’s called MAXX Machining Roughing HPC. Other CAM developers are sure to follow suit.

I also expect more machine control developers to expand their cycles to include trochoidal and peel-style toolpaths. For simple parts or a simple job, the operator can quickly create a program if a 3D model or CAM package isn’t available.

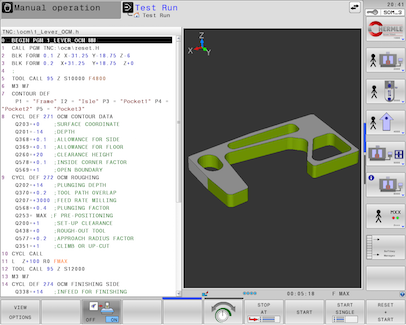

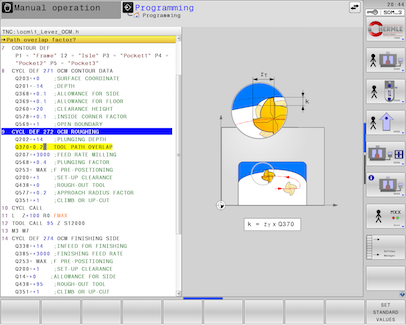

With our latest generation of NC software, we have the capability to rough a part with trochoidal movements using optimized contour milling (OCM) cycles. This is an option for our TNC controls. With these cycles, a user can rough a 2D contour, finish walls and floors if needed.

This brings us to the importance of making sure your machine tool’s CNC has a good motion control system or high-speed mode. To maintain the appropriate tolerance on the contour path, your machine must be able to accelerate and decelerate very quickly and accurately. If the machine cannot it can’t, the tool may gouge corners where it picks out material at high rate of speeds and where the acceleration/deceleration (accel/decel for short) is at its greatest.

To boost productivity further, the operator can adapt the spindle load by monitoring feedrate. We call this machine tool learning capability adaptive feed control (AFC). An option within our iTNC/TNC controls, AFC enables the operator to monitor and adjust the sensitivity/reaction of the feed rate, a unique parameter. For smaller tools, AFC can help prevent chipping in exotic metals. These adjustments help prevent load-up on the teeth for a few split seconds, which can prevent a reduction in tool life.

Tooling Manufacturers Get on Board

In the coming years, I expect to see more cutting tool manufacturers introduce high-speed machining (HSM) tools appropriate for trochoidal milling operations.

One such company is Fraisa USA in New Brighton, Minn. The HX-RNVS and XSpeed-H accommodate a wide range of applications from mold steel to high-hardened steels. Some of these tools incorporate more cutting edges (Z6 and Z8) and depth of cut up to 5xD (e.g., 10mm diameter x 50mm cutting depth). This is due to the small chip created, and thus these types of tools can push even higher feedrates due to an increase in teeth.

In closing, trochoidal and peel-style techniques are proven to save time and tool life in machining operations. If you‘re not using them, I encourage you to investigate this possibility on your existing equipment – if your machine tool can handle the requirements – or on your next machine tool purchase. If you have a newer machine, find operations where you may be able to try these techniques, then find the right tool, use a hydraulic or shrink-fit holder, and experiment with trochoidal techniques on your control or CAM system.

If you want to learn more about taking advantage of trochoidal milling and other features of the TNC control, you‘re invited to sign up for online or in- person classes at https://training.heidenhain.com/en_US/. I hope to see your there!