Space-Saving Automated Welding Package for Pipe Fabricators

Koike Aronson Ransome’s pipe-welding package incorporates the Cricket-I manipulator. Providing 20-IPM lift speed and 150-pound load capacity, the manipulator ensures productivity increases without sacrificing floor space.

Posted: February 9, 2021

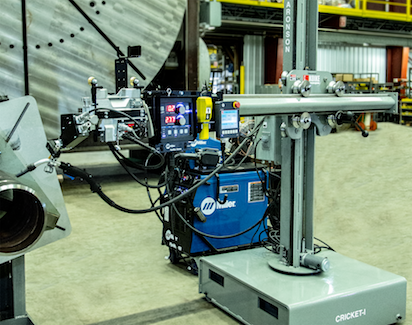

Koike Aronson Ransome (Arcade, NY) offers a pipe welding package that incorporates the Cricket-I manipulator, Wel-Handy Multi Next and WU-3 weaver mounted on the end of the boom.

The manipulator meets the need for fixed automation equipment compact enough to fit into small to mid-size fabrication shops. It provides 6 feet of powered lift and 6 feet of manual reach, lifts up to 20 inches per minute (IPM), and handles loads up to 150 pounds. It comes with a manual travel car, including v-wheels and fork truck pockets for mobility and mast rotation with lock for added functionality.

The package is configured to use the 3-inch-by-3-inch manual cross slide and built-in weaving functionality to increase quality and maximize productivity by automating pipe welding. Mounting brackets for control pendants and welding interface are included at the weld head, keeping all controls in one place. The Wel-Handy Multi Next is detachable and can be used as a stand-alone portable welding machine.