Metalworking Fluid Isn’t Just Another Consumable

Formulators spend significant resources to develop coolant that optimizes a machining process based on what materials, machine, and tooling a manufacturer is using. Don’t miss out on the product’s strategic value by being pennywise and pound-foolish.

Posted: February 5, 2021

SMOOTH OPERATIONS COLUMN

BY CHRIS PORSCH

Applying a lever to a heavy object is an age-old but powerful mechanical concept. As a tool, the lever amplifies a relatively minor input and delivers results of a substantially greater magnitude. Similarly, the “leverage effect” of finding the best metalworking fluid – a relatively minor cost in the production process – can deliver returns many times over.

Everyone understands the importance of having the right CNC machine, choosing the best cutting tools for the application, figuring out the workholding, and assigning the right operator to the job. These are the big costs attributed to manufacturing any part, along with overhead such as building and utilities and indirect costs like scrap.

Metalworking fluid is a fraction of the total investment, but has an outsized influence because it touches virtually everything in the shop, from tools to machines to employees. The idea that this often-overlooked input, which typically comprises around 0.5% of total manufacturing costs, influences the success of the other 99.5% of the endeavor is what we call the “leverage effect.”

Unavoidable Cost or Missed Opportunity?

Many shops don’t take time to consider the importance of using the appropriate coolant for an application. It’s often considered a commodity product and a necessary evil, on par with unavoidable costs like paper products or cleaning supplies. However, considering its ability to extend a drill or endmill’s effectiveness and service life, it has a wide-ranging impact on a shop’s other major cost centers.

Using the best metalworking fluid for a process extends tool life, increases cutting speeds, improves process stability, and reduces maintenance hours. The return on investment is clearly measurable, and total savings is multiplied by the number of machines in your shop. That is a significant leverage effect.

Consider an example of a multimachine cell producing similar components. Optimizing fluid to shorten cycle times and improve availability across three CNC machines could eliminate or delay the need to buy a fourth machine.

Identify Measurable Improvement Goals

Which metalworking fluid is the correct choice depends on factors specific to the shop environment, machining process, and material mix. Different types of fluid deliver different benefits.

Common improvement goals include:

- Reduce tool wear to extend tool life

- Visibly and measurably improve part finish

- Support faster cutting speeds for shorter cycle times

- Reduce maintenance time and disposal costs.

Let me give you just two examples.

In 2018, an Illinois machinery manufacturer was prompted to review its choice of metalworking fluid when operators noticed green staining and peeling paint on a Haas horizontal machining center. While resolving this maintenance problem was their primary motivation, managers also wanted to see if they could extend tool life by 10% to 20%.

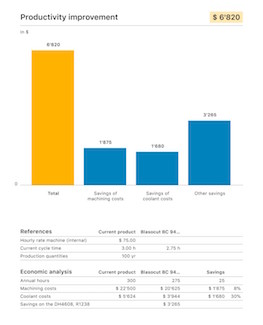

After a careful analysis and tests with a different product (Blasocut BC940SW), the maintenance issue was resolved and tool life increased by 27%. In addition, the amount of coolant required to top off the sump fell by 30%. Selecting the appropriate coolant for alloyed steel allowed a greater depth of cut, reducing cycle time by more than 8%.

In my second example, a manufacturer of hand tools wanted to change cutting oil to extend tool life in high-speed steel (HSS) and improve shop cleanliness. The per-gallon cost of the new product (Blasomill 10) was twice as much as the former product, but the shop used one-third the amount of fluid. The manufacturer would pay a higher price per unit, but would buy less and have less to dispose of. Tool life increased by 20%, with the greatest improvement seen on the most expensive tools. Total annual savings? More than $185,000 net on a $22,000 investment.

Start With A Situational Analysis

There are specific steps to reliably estimate potential cost improvements like these. The first is a situational analysis that includes a review of the local water quality; types of materials; cutting processes; and machine capabilities, such as high-pressure systems.

Water quality varies widely depending on what area of the country your shop is in and how your water’s treated. It’s extremely important to the success of water-miscible coolant, and should be tested and adjusted if needed. Achieving the right degree of water hardness significantly affects emulsion stability and sump life.

Then it’s time for a real-world test to prove out the proposed process and measure the results and cost savings. Admittedly, testing a new metalworking fluid isn’t as easy as trying out a new end mill. The process can require hours of downtime to empty the sump, thoroughly clean the machine, and refill it with the new product.

Our laboratories house a wide range of CNC machines to make this process easier. When testing a new product, we configure our equipment to match as closely as possible the customer’s shop conditions. Our employees draw on extensive collective experience gained from a wide range of manufacturing environments, plus machine know-how and process and materials expertise, to suggest the most cost-effective solution for a particular machining application or process. The data they generate shows potential savings before the customer begins any maintenance work.

Improve Employee Satisfaction

While the environmental benefits of selecting the right metalworking fluid are somewhat less quantifiable, they’re no less important.

Operators regularly expose their skin to coolant and the aerosols can be inhaled. High-quality fluids are made from raw materials that won’t harm people or the environment. They’re highly stable emulsions with the correct pH range and are free of bactericides to protect employees from allergies and skin irritation. This means a cleaner shop and machines, improved air quality, and better human compatibility.

The result is greater employee satisfaction, which is perhaps the greatest leverage effect of all.