How to Easily Automate Vertical Machining Center (VMC) Tending

With Quick and Simple Startup of Robotization (QSSR), Fanuc simplifies the process of connecting and programming a Fanuc robot or cobot. The all-in-one package enables operators to program the robot using the machine’s CNC.

Posted: February 11, 2021

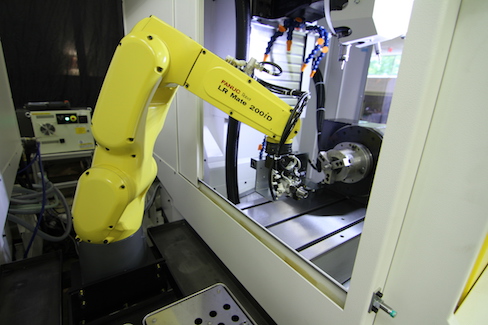

Quick and Simple Startup of Robotization (QSSR) from Fanuc America Corp. (Rochester, MI) is a complete package that simplifies connecting and programming a Fanuc robot or cobot to a Robodrill vertical machining center (VMC). Providing setup, programming, and operation, QSSR makes it easy to automate machine tending by implementing a variety of standard components and options.

A high-speed Ethernet cable connects the robot to the machine.

Operators and machine tool builders program robots through the Fanuc CNC in ISO standard G-code format, eliminating the need to hire programming specialists or train employees who aren’t familiar with programming language. Instead of a teach pendant, the robot is programmed and operated through the CNC user interface. The QSSR G-code feature is available on CNC Series Oi-F, Oi-F Plus, 30i-B and 30i-B Plus.

Two QSSR packages are available:

- Standard (yellow robots) is for mass production with short cycle times because the focus is on speed. It includes a Fanuc robot and base, Interface II robot-to-machine connection, configurable side door, sample programs, and coolant drip pan.

- Select basic (collaborative/green robots) is for producing smaller quantities with longer cycle times because the focus is on flexibility. It includes a Fanuc robot and mobile base, Interface II robot-to-machine connection, front servo door, iRVision, sample programs, and an area sensor.