High-Force Actuators Support Robotic Sheet-Metal Welding

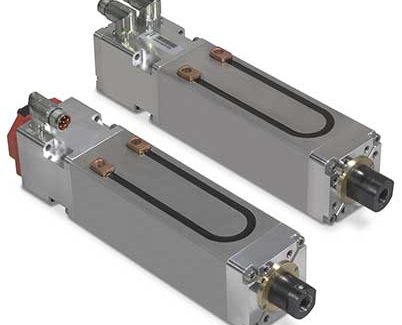

Tolomatic’s CSW and CSWX Compact ServoWeld welding gun actuators for robotic spot welding integrate a 3,507-lbf and 4,047-lbf, respectively, actuator into a hollow-core servo motor for faster resistant spot-weld cycles.

Posted: February 9, 2021

Designed for high-production sheet-metal welding applications and automotive body-in-white resistance spot welding, Tolomatic’s (Minneapolis, MN) ServoWeld high-force actuators for seventh-axis robotic applications are available in a smaller, slimmer design. Available in patent-pending models for steel and aluminum weld applications, the CSW and CSWX Compact ServoWeld actuators deliver up to 30 million welds (CSWX) in typical robotic welding applications along with increased force and speed.

Force range and speed easily adapt to increases in production demand. The roller nut on the Compact ServoWeld CSWX handles more than 95% of applications with C, X and pinch weld guns. The CSWX provides up to 18 kN of pressing force (4,047 lbf) in a 90-mm frame. Top-speed C-gun performance is 10.5kN of force (2,023 lbf) and 700 mm/sec (27.5 in/sec). Options include integrated force feedback, manual override and long stroke.

Providing 15.6kN (3,500lbf), the CSW is designed for lower-force and lower-duty-cycle applications (20 million+ welds) for C, X and pinch weld guns. Top speed C-gun performance is 7.9kN (1,641 lbf) and 700 mm/sec (27.5 in/sec).

Both models include mid-trunion mounting to easily adapt to a variety of mounting locations, four standard stroke lengths, and force repeatability of plus or minus 3% for the actuator’s life. Integrated anti-rotate and integrated water cooling options are available.