Design the Ideal Floor Layout for Cobotic Production and/or Assembly

Delmia Robotics’ software from Dassault Systemes maximizes automation initiatives by enabling manufacturers to design and virtually test a drilling-and-riveting, arc welding, spot welding, and/or material handling line before rolling it out.

Posted: February 8, 2021

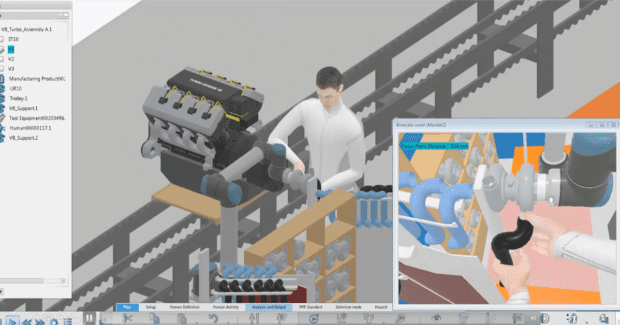

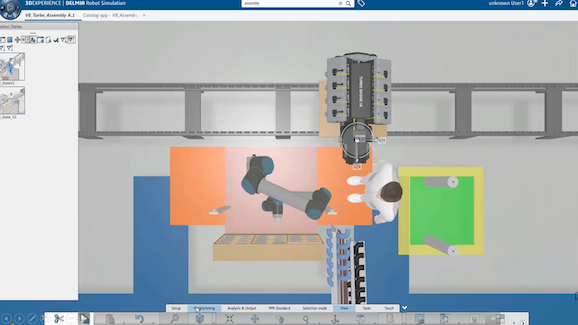

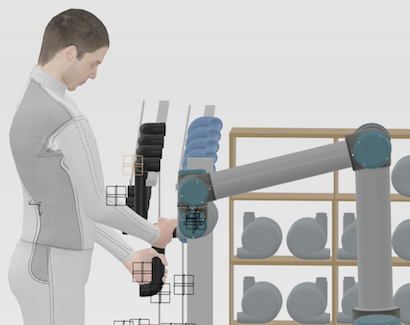

Delmia Robotics software from Dassault Systemes Americas Corp. (Waltham, MA) saves time and money when automating by providing an interactive 3D environment where engineers can design, simulate, program, and validate a work cell before implementing it. Cobotic and robotic processes such as drilling and riveting, arc welding, spot welding, material handling, painting, and polishing can be programmed and validated for any size factory.

The platform ensures a production or assembly line will perform as expected by including tooling and auxiliary equipment in models and simulating the entire manufacturing environment and product flow. In addition to facilitating the rollout of new processes, it makes managing change when products or processes are updated much easier.

Users can assess equipment design and layout to maximize productivity by reducing operator fatigue and ensure compliance across multiple platforms.