Autonomous Tube/Wire Bender Enables Lights-Out Production

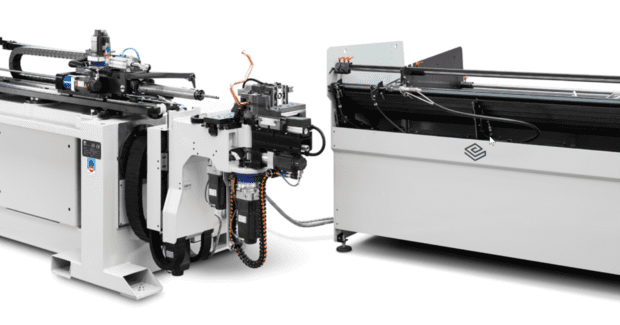

Featuring a compact layout, integrated loading/unloading capability, and easy-to-use programming software, BLM Group’s Smart Bender enables an operator to go from design to part in one click and walk away.

Posted: February 10, 2021

The Smart Bender from BLM Group USA (Novi, MI) provides a turnkey solution for manufacturers seeking safety and autonomy. Capable of handling right- and left-hand bending of tube, wire or hybrid tubes (those with flanges, end forms, etc.) up to 1.1 inch (28mm) round, the machine is particularly well-suited to the complicated shapes and multiple-radii tubes used in the automotive, air conditioning, heating and refrigeration industries.

Programming software that takes the operator to go from idea to part in one click and a wide range of loading/unloading options enables nonstop operation without a dedicated operator.

All-electric axis control enables bend radii of less than 1D as well as complex shapes with multiple radii or for preassembled tubes with flanges, end forms or fittings with perfect repeatability and consistent accuracy. Stack tooling provides multiple-radius capability.

VGP3D programming software eliminates the need for a bender setup specialist and the risk of collisions during part tryout. The program calculates cycle time so manufacturers can quickly generate accurate quotes and production estimates, and automatically generates the part program once feasibility is verified. Bend positions, tooling information, and power parameters are saved together; when a job is repeated, the operator mounts the tools and recall the part program for quick setup and changeover.

High productivity and low price provide a competitive per-part cost. Savings are also achieved through 2kW energy consumption.