Material-Removal Kit for Demanding Robotic Applications

ATI Industrial Automation’s electric RCE-710 has built-in radial compliance with single-axis lockout to facilitate robot programming. Available as a complete end-effector package, the robust tool handles a wide range of material-removal tasks.

Posted: January 4, 2021

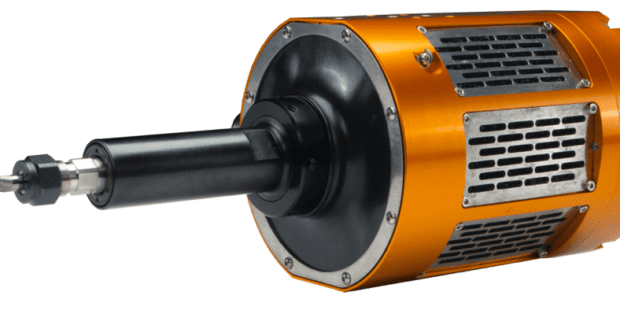

Available as a complete end-effector package, the RCE-710 from ATI Industrial Automation (Apex, NC) comprises deburring tool, power and signal cables and connectors, and an easy-to-use controller. The robotic material-removal tool performs a wide array of tasks with carbide burrs; brushes; flap wheels; unitized wheels; and other cutting, grinding, and polishing media.

The 12-pound tool is built to withstand demanding robotic applications such as weld spatter removal, blending, and polishing, featuring large bearings and a variable-speed motor with a range of zero to 13,000 rpm. Built-in adjustable compliance streamlines robot programming and compensates for part and fixturing misalignments. The motor rotates clockwise and counterclockwise and produces continuous torque on the workpiece for consistent processing.