Flexible Robotic Welding System Reduces Nonvalue-Added Labor by 60%

U.S.-based ACS Industries had a lock on the market for standard attachments – buckets, forks, blades, etc. – for construction equipment, but needed to cost-effectively fabricate specialized implements for related markets. Six-axis robotic welding clinched $1.5 million in new business while lowering labor costs 60%.

Posted: January 25, 2021

BY STEPHANIE JOHNSTON

Located in a 100,000-square-foot facility in Kent, Ohio, ACS Industries Inc. fabricates attachments – buckets, forks, blades, couplers, and other implements – that enable construction equipment to dig, clear, demolish, and mine. Best known for introducing the market to a quick-coupling system that speeds exchanging one attachment for another, the company also developed the first front-locking excavator coupler system and a bucket with a monolithic floor design for the hot slag industry.

Although the company makes heavy material-handling equipment the U.S. Marine Corps uses worldwide, its customer base is primarily North American. Like many manufacturers, the Great Recession prompted introspection that resulted in significant change.

“We always identify opportunities around pain,” says CEO Joe Zeno. “If we can understand what the pain is and come up with a better solution, that’s an opportunity. We looked at our distribution channels and said, ‘We need to broaden those channels.’”

The company reorganized into two primary business channels: product line and engineered product. Product line includes tools for standard construction activities such as site clearing, underground water and sewer development, and road building. Engineered product focuses on specialized implements for industries such as aggregate mining and steelmaking.

ACS was using robotic systems to fabricate the product line, but engineered product was relatively new. The company had dabbled in the market, and there was significant competition. To design and deliver more-innovative products faster and less expensively, the company contacted four robotic welding technology providers.

“Of course, the evaluation most people do is, ‘How much is this going to cost?’” says President Bob Willoughby. “While cost was a consideration, we went with what we felt would bring the biggest value to our company, customers and employees. We evaluated a lot of avenues: What will this piece of equipment do for us? Is it going to do exactly what we think it’s going to do?”

Ultimately, ACS decided to work with Cleveland-based Lincoln Electric.

One System, Many Welds, Flexible Capabilities

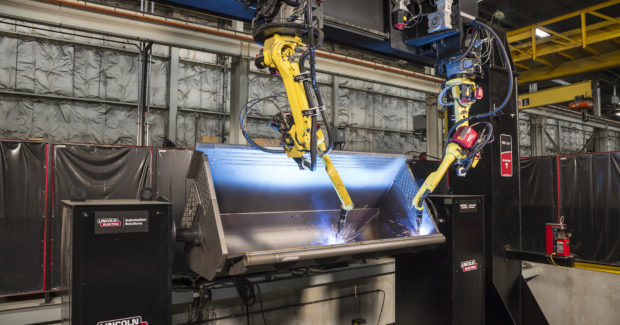

ACS wanted to run a range of equipment on the robot. After almost six months of meetings and exchanging drawings and files with Lincoln Electric application engineers and testing configurations, the result was an overhead gantry system with two Fanuc robotic arms that welds buckets up to 22 cubic yards and 28,000 pounds used in quarries and steel mills.

The assembly is mounted in a 5-foot-deep pit – 40 feet long by 20 feet wide – in the factory floor to keep the 26-foot-high robot under the overhead crane. The system welds the bucket in six axes with a variety of wire diameters, from 0.035-inch to 1/16-inch, at each axis.

The process isn’t as simple as fitting a bucket in the fixture. The buckets may dig at the face of a granite wall or handle molten slag at 2,800 degrees out of the furnace, so the welding process impacts how they perform.

“We do anywhere from 3/8-inch fillet welds to 1-inch groove welds that require multiple-pass,” says Willoughby. “Anything above 3/8-inch are multiple-pass welds that require multiple movements and multiple programs in the machine in all those axes. We also often weld two grades of materials, which requires two processes. The machine has to pause and we have to change to the proper wire. Lincoln helped us develop those processes and select the wire and gas required to weld the different grades.”

60% Reduction in Nonvalue-Added Labor

In addition to helping gain traction in a new marketplace, automation is boosting efficiency.

Nonvalue-added labor fell more than 60%. Instead of parking on the factory floor for five weeks as when they were manually welded, buckets stay there for days. In addition, efficiency has gone from about 60% to 80%. “I don’t know that it’s possible to maintain 100% on a continuing basis, but it’s a goal that we continue to work toward,” says Willoughby.

“All of that’s enabled us to offer quality products in a very price-competitive way and, in most cases, at a significant pricing advantage over our competitors,” says Zeno.

In fact, as hoped, ACS has made inroads into untapped markets. The company partnered with an OEM on a bucket-development program that increased orders by $1.5 million and accelerated growth in the aggregate mining and steel production industries.