Software Enables Both Additive And Subtractive Applications

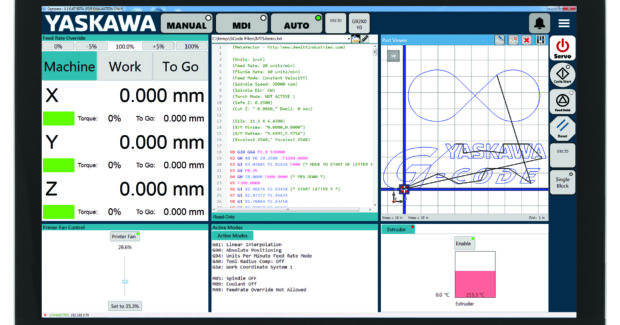

When coupled with an MPiec controller, machine tool builders and experienced CNC programmers can use Yaskawa Compass graphical user software to design HMI hybrid machines as well as 3D printing, shape cutting, and robotics.

Posted: December 3, 2020

The Yaskawa Compass graphical user interface tool from the Drives & Motion unit of Yaskawa America Inc. (Waukegan, IL) saves machine tool builders and experienced programmers time and effort.

The easy-to-customize HMI package for CNC applications integrates with existing computer code. Coupled with the MP3300iec motion controller, the CNC navigator provides preconfigured plug-ins for extruder, spindle, temperature control, stepper control, linear and rotary tool changer, and 2D path planning that users simply drop onto their screens. The plug-ins are developed in the C# programming language so machine builders and programmers can create and import their own plug-ins.

To supplement the use of Compass with MPiec controllers, the company added advanced motion control features to its MotionWorks IEC library. These include bed-leveling compensation, extruder pressure advance control, tangential control and ability to create custom G-codes and kinematics.

Compass is built around a column-based format and includes an extensive style library. As a result, tool builders can brand screens with company colors and graphics, include core machine attributes, and address customer needs with little programming requirements.

Yaskawa’s Drives & Motion division manufactures industrial automation equipment including low- and medium-voltage variable-speed drives, servo motors and amplifiers, machine controllers, spindle drives and motors, and low-voltage industrial switch products.