Quality Mass Production with Metal Binder Jetting IS Possible

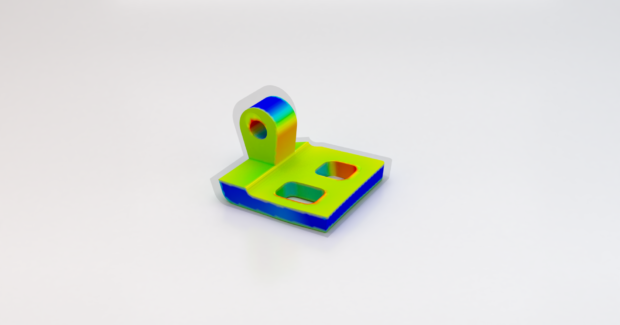

Hexagon’s Simufact Additive powerful and scalable process simulation environment for first-time-right optimization of metal binder jetting (MBJ) predicts and automatically corrects for final distortion and residual stresses of 3D-printed parts.

Posted: December 3, 2020

Metal binder jetting (MBJ) has several advantages over powder bed fusion (PBF): High volumes can be produced with minimal spacing, no support structures are needed, and larger lot sizes are possible. It could replace low-volume, high-cost injection moulding for everything from automotive and aircraft parts to medical applications and, because high resolution is possible, reduce costs and lead times for complex lightweight parts such as gears or turbine wheels.

A key obstacle to realizing these benefits has been the inability to predict the extent of shrinkage the sintering process will cause, which the models used for other processes can’t accurately predict. Costly physical trials have been required to perfect the printing of each part, preventing many manufacturers from taking advantage of MBJ’s low cost and flexibility.

Simufact Additive from Hexagon Manufacturing Intelligence (North Kingstown, RI) enables manufacturers to predict and prevent at the design stage, without specialist simulation knowledge, the distortion caused by thermal strain, friction, and gravity. Sintering-induced mechanical stress is also predicted, indicating where defects might occur. Because the software compensates for all these factors, parts are printed as they’re designed. Manufacturers can make changes earlier in product development, greatly reducing costly redesigns and the number of parts that must be scrapped or reprocessed.

The software automates model setup, preparing the CAD or computer-aided engineering (CAE) file for manufacturing simulation. Simulations can also be automated through Python scripts. To validate the sintering compensation and increase confidence in quality, the optimized geometry can be immediately compared to both the initial design (CAD) geometry and a metrology scan of a manufactured part within the interface.