Multiaxis CO2 Lasers Close the Gap Between Novice and Experienced Operators

VZ10 and VZ20 laser cutters from MC Machinery feature intuitive CNC control with one-touch teach functions that greatly reduce keystrokes, cutting onboarding time for new operators virtually in half.

Posted: December 28, 2020

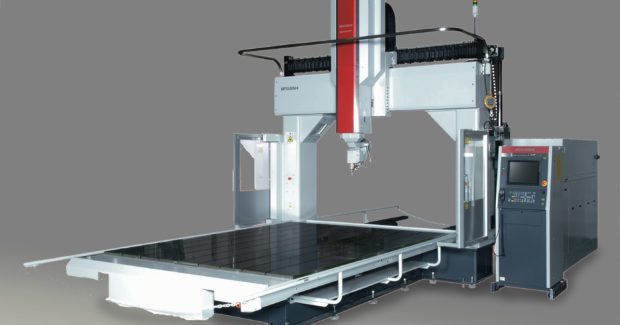

Featuring Mitsubishi’s easy-to-use LC30T control interface, the VZ10 and VZ20 laser cutters from MC Machinery Systems Inc. (Elk Grove Village, IL) provide accuracy and flexibility for complex 3D laser applications.

A belt-drive system instead of a pinion-gear system increases reliability. Dross Reduction Control combines real-time power ramping with acceleration or deceleration to reduce thermal influence and dross adhesion, decreasing the need for post-process deburring.

Three-axis cross-flow resonator delivers the industry’s highest cutting power per watt. Its simplified design eliminates the need for expensive glass tubes and turbine blower systems and requires two to five times less maintenance than other lasers.

The VZ10 features:

- A focal lens for faster processing of thin materials.

- Zero-offset head for a wider processing area and easier setup.

- Axial movement for higher overall processing speed.

- Z-axis is 30% faster than previous models.

The VZ20 is available with a 6th axis and comes with exchangeable head options:

- A thick-plate head for cutting 0.75-inch mild steel.

- A high-speed welding head.

- A noncapacitive head with slim design for reduced workpiece interference.

- An H-axis head that automatically adapts to part height when processing formed parts.

The 15-inch touchscreen color display allows better visual recognition and operability. The machines have a 20GB hard drive, Windows-based numeric control (NC), and USB port. Optional DiamondSoft 3D CAD/CAM software enables offline programming.