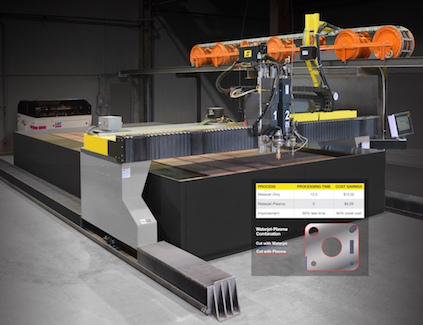

Large-Gantry Dual-Technology Cutting System

ESAB’s Hydrocut HDX combines waterjet’s precision with plasma’s speed in a work area that’s 18 feet wide and 56 feet long. Combining technologies cuts per-part cost in half and enhances workplace safety by reducing handling needs.

Posted: December 28, 2020

The Hydrocut HDX from ESAB Welding & Cutting Products (Annapolis Junction, MD) can be equipped with up to four waterjet cutting heads, two oxy-fuel stations, and two plasma stations (including the company’s DMX plasma beveller) as well as tools for high-speed plasma marking, pin stamping, or inkjet plate marking. Combining these technologies and capabilities in a work area 8 to 18 feet wide and 56 feet long can lower part cost by up to 60% and enhance safety by reducing part handling.

Waterjet technology provides high precision on contoured shapes, a smooth edge with no bevel, no heat-affected zone, and no dross to produce perfectly finished parts that don’t require secondary cleanup or machining. It also cuts almost any material and can handle sheets up to 6 inches thick. However, it’s comparatively slow and expensive. By combining waterjet with plasma on the same gantry, customers can produce more parts for lower cost compared to waterjet-only systems.

There are two waterjet intensifier pump options: the KMT Streamline SL-VI intensifier (55 KPSI) or Plus pump (60 KPSI) in 30, 50 or 100 horsepower for standard cutting; and the KMT Streamline Pro-III (90 KPSI) intensifier in 60 or 125 horsepower for the fastest speeds and lowest cost per part.

The Hydrocut HDX is based on ESAB’s Suprarex gantry with dual-linear rail Y-axis guiding system to deliver the high dynamic accuracy necessary to produce high-quality parts with high-cut precision. Maximum speed is 1,000 inches per minute (IPM). Both X and Y axes are protected with bellow covers to keep abrasive materials and moisture away from the rails.

The Vision T5 controller features a touchscreen interface, EasyShape part program generator, EasyNest option, and built-in process database to enable users to quickly and easily set up new cutting routines.