Large-Format 3D Printer Doesn’t Need Support Structures to Ensure Quality

Featuring a build volume of 600 mm x 550 mm, VELO3D’s extra-capacity Sapphire XC uses Flow print-preparation software and Assure quality assurance software to manufacture high-quality parts without using support structures.

Posted: December 3, 2020

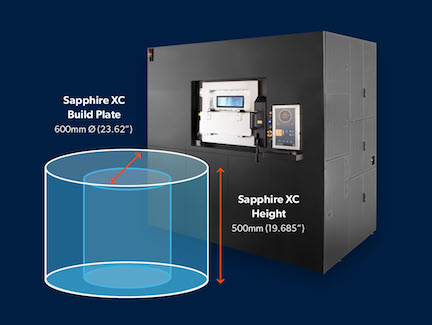

Featuring eight 1,000W lasers, the Sapphire XC (for extra capacity) laser powder bed fusion (LPBF) 3D printer from VELO3D (Campbell, CA) is up to five times faster than its predecessor, reducing cost per part by up to 75%. The XC uses the same optical-train design, recoater technology, gas-flow technology, and metrology as the Sapphire, but its build volume is 600 mm by 550 mm.

The company’s end-to-end digital manufacturing solution for producing metal parts consists of the printer, Flow print-preparation software and Assure quality assurance software. The integrated system enables support-free 3D printing without comprising quality.

Qualified material alloys include Aluminum F357, Titanium 6AI-4V, Inconel 718 and Hastelloy X.