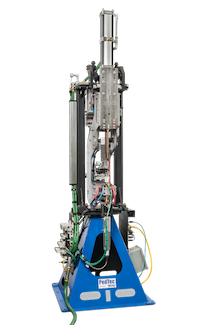

High-Speed Fastener Welding System

CenterLine introduces two SoftMount inverted-nut gun configurations for a high-speed fastener welding system that streamlines the process from operator load to finished part, providing higher throughput than standard welding solutions.

Posted: December 30, 2020

CenterLine’s SoftMount gun is available in two configurations: standard feed process (SFP) for nut and stud welding applications, and inverted feed process (IFP) for nut welding and special applications.

Designed to mechanically fine-adjust its position to a stamped hole to consistently projection-weld a fastener, the SoftMount gun from CenterLine Ltd. (Windsor, Canada) is ideal for robotic applications where part dimensions, hole locations, or tooling are slightly inconsistent. It’s available in two configurations:

- Standard feed process (SFP) for nut and stud welding applications.

- Inverted feed process (IFP) for nut welding and special applications.

- A compliance mount assembly is set far enough from the weld plane that it doesn’t introduce variation to the welding process. Other standard features include:

- Patented VeriFast LVDT for accurate fastener detection, orientation, and measurement of set down.

- Quick fastener placement (QFP) unit for rapid nut feed in the IFP configuration.

- C-frame mounting style to return the gun to the initial position without external force.

- Low-impact actuator choices for a wide range of welding forces.

- PedTec weld gun stand.

- Full leveling adjustment for reliable setup.

Subscribe to learn the latest in manufacturing.

More fabricators are using larger-diameter grinding wheels and flap discs for their grinding, material removal, and blending applications instead of 4.5-inch options — and with good reason.

More fabricators are using larger-diameter grinding wheels and flap discs for their...