3D Printer Processes Wider Range of Metal Materials

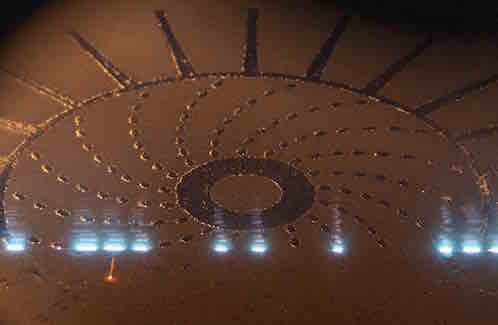

Unlike electron beam and laser powder bed fusion (PBF), Wayland Additive’s Calibur 3 uses NeuBeam technology, which focuses heat on the part instead of the process bed. As a result, the machine is able to process refractory metals and highly reflective alloys.

Posted: December 3, 2020

Designed specifically for production applications, the NeuBeam process developed by Wayland Additive Ltd. (Huddersfield, England) eliminates many compromises that powder bed fusion (PBF) users have had to make for part development as well as full production.

NeuBeam overcomes the inherent instabilities of electron beam PBF and the internal residual stresses typically associated with laser PBF to provide a truly stable and flexible process. The charging issues that make electron beam PBF so unstable are neutralized via physics principles developed by the semiconductor industry. Also, NeuBeam is a hot “part” process rather than a hot “bed” process. This creates parts free of residual stresses because the high temperatures are applied only to the part and not the bed, ensuring free-flowing powder post-build (no sinter cake) with less energy consumption.

The process is compatible with materials, such as refractory metals and highly reflective alloys, that aren’t compatible with electron beam or laser PBF.

The machine incorporates fully embedded in-process monitoring capabilities that provide full oversight during every build and ensure full traceability for every part.