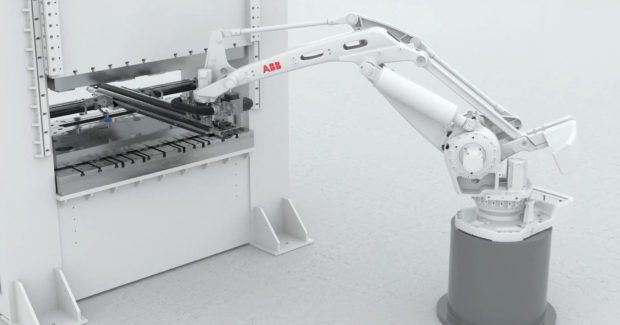

Robot-Based Press-Automation Solution

ABB Robotics’ IRB 760PT is the basis of two configurations – the FX and the TRX – that optimize speed and minimize die interference in press-tending applications. The robot provides a flexible automation solution that’s easily repurposed to handle changing requirements.

Posted: November 23, 2020

ABB Robotics (Auburn Hills, MI) expands its line of 4-axis IRB 760 robots with the IRB 760PT (for “press tending”). Built to automotive industry standards, the flexible IRB 760PT is 25% faster than other robot-based press-automation solutions.

A revised design reduces interference in the 4th axis, enabling the robot to move freely without colliding with equipment such as press clamps. Able to move 992 pounds (450 kg), the robot reduces the time, cost, and disruption associated with repurposing dedicated press-tending machines. Thanks to its ability to automatically change tooling, it can be quickly adapted and reprogrammed to handle new products without the need for re-engineering.

Featuring a reach of 10.43 feet (3.18 meters), the IRB 760PT is the fundamental component of the IRB 760FX and the IRB 760 Twin Robot Xbar (TRX).

Combining the IRB 760PT with a linear 7th axis, the IRB 760FX offers the flexibility required to work with large- and medium-size panels and execute special processes such as part reorientation, tilting and part separation.

Two IRB 760PT robots combined to work in tandem across 10 axes create the IRB 760 TRX. This is the fastest robot-based solution on the market for loading and unloading presses with long inter-press distance without having to modify the press. With a maximum output of 16 parts per minute, the TRX is ideal for high-speed press-automation applications.

ABB’s StampWare software with graphical programming wizard that decreases training time is available on the robot’s FlexPendant for maximum simplicity.

The robot is covered by RoboCare, a three-year warranty package that includes ABB’s Connected Services, where ABB experts monitor robots and suggest optimized maintenance to increase productivity.