Four Tools for Even Better Robotic Welding

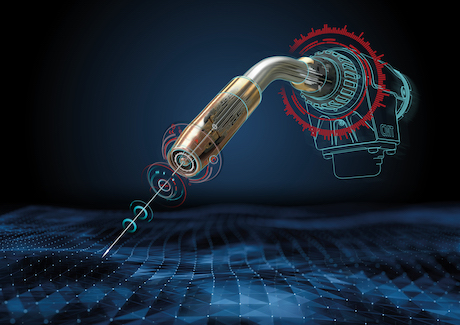

Fronius increases seam quality without slowing cycle time with robotic assistance systems by making the wire electrode a sensor as well as filler metal. This eliminates the time and expense of maintaining sensor hardware and doesn’t restrict component accessibility.

Posted: November 10, 2020

With WireSense, SeamTracking, TouchSense, and TeachMode, Fronius USA provides four robotic assistance systems that prevent cycle time losses and ensure reliable seam quality when using the company’s TPS/i welding platform.

With WireSense, the electrode wire acts as a sensor as well as filler metal, improving accuracy by enabling the robot to know where the edge of the sheet is and how high it is. A defined threshold somewhat below the edge height is determined in advance. When the platform detects values above the threshold during the scanning process, the power source immediately outputs a digital touch signal with height value.

The controller uses this signal to save the robot’s positional data and correct its path by comparing it with the target data. With component inaccuracies recognized and compensated for, the robot welds in exactly the right location. Edge detection is possible for material thicknesses greater than 0.5 mm and sheet thicknesses up to 20 mm.

WireSense also uses edge height to calculate air gaps between the sheets. Welding jobs with associated air gap data that are saved enable the robot to automatically adjust parameters for each job’s air gap dimension.

In this way, WireSense counters tolerance fluctuations in both the component and clamping technology. The assistance system ensures reliable seam quality and reduced rework and component rejects by up to 100% without additional sensor hardware.

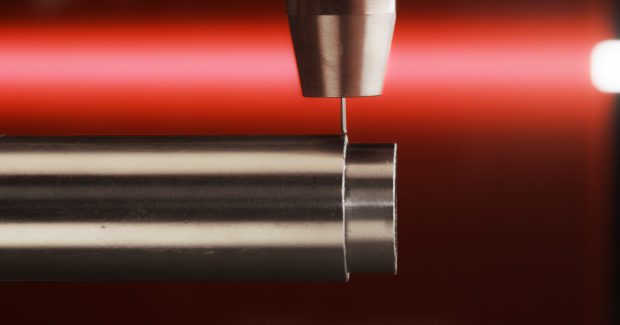

TeachMode speeds the teach process by keeping the welding wire from being bent when scanning the component. A reversing wire movement begins as soon as the pre-set stick out is undershot by the robot, and a visual/audible signal tells the operator to move the welding torch away from the component. This saves the operator from having to remove the deformed wire or re-measure the stick out.

Particularly useful in the manufacture of railway or construction vehicles,

SeamTracking improves the quality of fillet welds and prepared butt welds. The robot compares measured values against welding parameters to detect deviations in welding position and automatically corrects the pre-programmed path to weld in the correct position.

To compensate for component and clamping tolerances, the robot can use TouchSense to check the position of fillet welds automatically before each weld. To do so, the robot touches the two sheets with the wire electrode or the gas nozzle – which are supplied with a low-sensor voltage – at the defined beginning and at the end of the weld seam. The signals in the short circuit enable the perfect starting point to be determined.