Updated CAD/CAM, CNC/MTB Software Component Platform

ModuleWorks’ 2020.08 CAD/CAM software includes performance- and quality- enhancing features for rotary machining, additive manufacturing, 3-axis machining, simulation, and the ModuleWorks multiaxis post processor (MultiXPost).

Posted: October 9, 2020

From standard products to exclusive development projects, software component provider ModuleWorks (Aachen, Germany) enables customers to optimize CAD/CAM solutions and connect to CNC/MTB systems to increase their competitiveness. Highlights of Version 2020.08 include performance- and quality- enhancing features for rotary machining, additive manufacturing, 3-axis machining, simulation, and the ModuleWorks multiaxis post processor (MultiXPost).

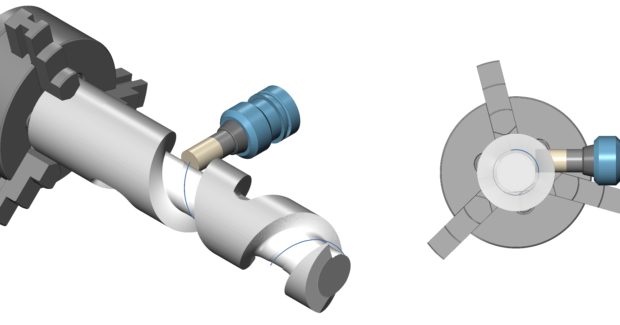

With an axis offset for roughing cycles with rotary machining, the tool cuts with the cutting edges instead of the tool center to achieve more stable cutting speeds and close-to-diameter cutting with nonspherical tools. The offset is always in the opposite direction of rotation and automatically changes position when the rotation direction changes. This movement is linear to prevent damaging the tool and ensure a safe cutting process.

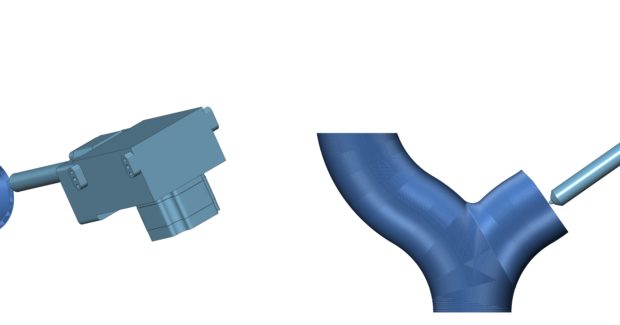

ModuleWorks 3+2 axis additive manufacturing uses the full capabilities of 5-axis printing machines to print extreme overhang areas without the need for support structures. This accelerates the manufacturing process and delivers a higher quality finish with reduced staircase effects.

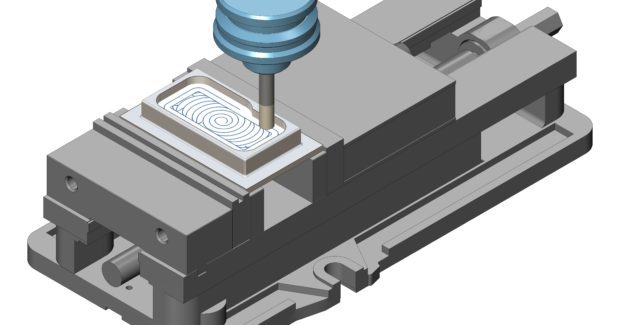

For 3-axis machining, there’s a profile pass for adaptive and offset roughing. To improve quality, additional cuts are added along the part boundaries to remove any remaining uncut cusps. A range of advanced options, such as cutter compensation and tangential arc, gives users full control over toolpath creation and makes it easier to create the finishing pass.

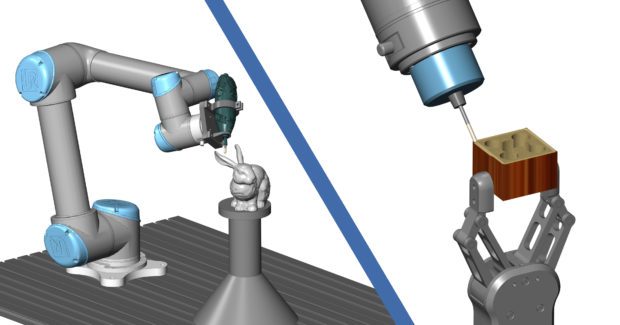

MultiXPost opens possibilities for generating G-code for N-axis machines and for simulating robotic applications. To provide full control over the machine movements, MultiXPost offers a range of parameters and returns the axis values that can be used to drive a simulation or generate an NC G-code file.

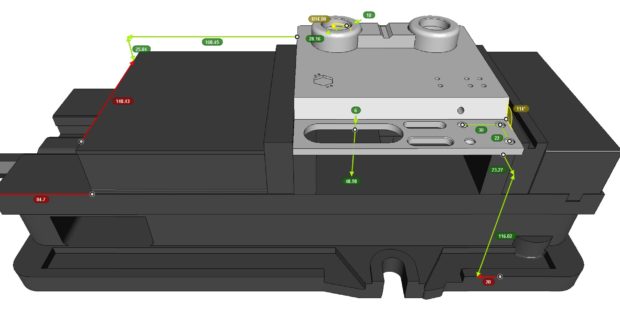

The smart-measure touchscreen tool quickly and accurately measures the stock and arbitrary meshes. Automatic feature identification and intelligent snapping help users set precise measurement points and then use the convenient drag-and-drop functionality to measure distances between the stock and the machine as well as depths, clearances, angles, and radiuses.