Tool-Grinding Software With Form Compensation Feature

NUM launches form compensation option for Numroto tool grinding software. Compared to most competitive products on the market, the software provides a much more direct and efficient path between tool design, manufacture, and verification. NUM’s new form compensation option is compatible with Numroto version 4.1.2 or later.

Posted: October 5, 2020

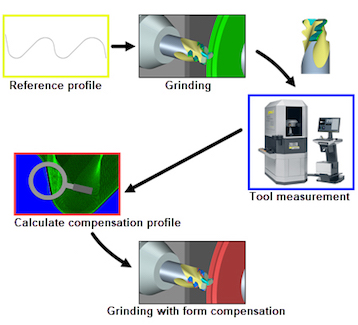

A form compensation option for NUMROTO tool grinding software from NUM Corp. (Naperville, IL) increases process accuracy and consistency by closing the loop between CNC tool grinding and measurement. By automatically compensating for process variables such as temperature fluctuations and wheel wear, the system is likely to prove especially helpful for manufacturers of specialist precision tools with strict production standards.

Operators seeking to maximize the accuracy of tools produced on CNC grinding machines generally use a coordinate measuring machine (CMM) to obtain probed measurements of the part to tweak the production process during subsequent machining operations. Until now, NUMROTO users processed the CMM results with third-party compensation software running on an external computer before feeding a suitably corrected target profile back into the CNC machine.

Developed in conjunction with several key end users, NUMROTO’s new capability eliminates the need for third-party software. Data exchange between the CMM and the CNC machine is handled by XML interface or by export/import of the DXF file via a local area network.

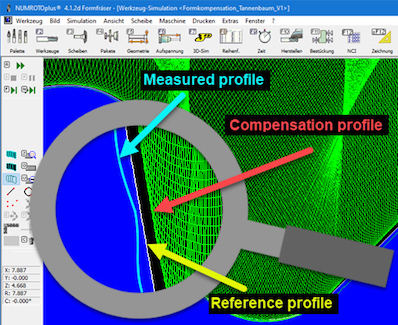

Advanced filtering algorithms create a very smooth and precise compensation profile. The software always calculates the orientation of the grinding wheel and the path speed from the original profile, so that only the position of the contact point on the cutting edge is compensated – not the orientation of the grinding wheel. This ensures tool surface quality isn’t affected by the compensation.

The form compensation option is compatible with NUMROTO version 4.1.2 or later.

Launched in 1987, NUMROTO software has become the preferred choice for many of the world’s leading manufacturers of CNC machines for the production and re-sharpening of end mills, drills, step drills, form cutters, and many other tools. It’s used on more than 6,000 machines worldwide.