Software Simplifies Part-Cutting Programming and Quality

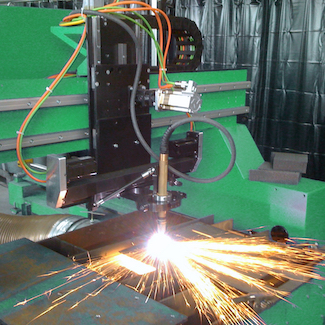

NUM’s NUMcut for CNC water jet, laser, and plasma beam cutting machines increases efficiency by incorporating CAD/CAM postprocessor computing resources. Real-time analytical functions for water jets improve quality by automating cutting speed and path.

Posted: October 9, 2020

The latest version of NUM Corp.’s (Naperville, IL) software for CNC water jet, laser, and plasma beam cutting machines embodies Industry 4.0 connectivity principles. Featuring an entirely new human-machine interface (HMI), NUMcut’s integrated CAM/postprocessor module simplifies programming and includes two real-time analytical functions to improve water jet cutting accuracy and quality.

Users generally prepare part programs for CNC cutting applications upstream of the machine in the production area on some form of CAD/CAM system. A key element involves post-processing the resultant ISO file to incorporate machine-specific cutting data. This highly iterative procedure can lead to interpretation errors and time-consuming resolution of machining issues.

To shorten the path, NUMcut includes a machine-resident CAM/postprocessor module. The only data that must be transferred to the machine before commencing cutting operations concerns part geometry and desired quality of each cut. This data can be derived from virtually any type of CAD/CAM software running, for example, on a standard PC.

All other necessary data, such as cutting speeds, abrasive quantity as a function of the material to be cut, etc., are calculated by the control system. The CAM/postprocessor module’s technology database contains all the information the system needs to automatically generate an executable part program. The values in the database are preloaded by the machine manufacturer, and can be modified or added to by users if necessary – for example, to accommodate new materials.

The database can be located on individual machines or stored on a network drive for access by several machines.

The HMI displays all files in a clear, unambiguous style. Using the CNC system’s touch-sensitive screen, the operator can determine each successive machine action by clicking and dragging icons from the pool of files into a job list. The job being processed by the machine and cutting tool position within the job are marked graphically. If required, the operator can change the job list while it’s being processed to accommodate different production needs, such as express deliveries.

NUMcut also offers two real-time analytical functions for water jet cutting applications. During cutting, processing speed must be decreased before corners to maintain quality by reducing the cutting jet’s wake. Using data from the technology database, NUMcut’s adaptive feed control (AFC) function analyses the path geometry and automatically optimizes cutting speed to suit the curve radius or corner angle.

Another inherent characteristic of water jet cutting is that the shape of the kerf changes with cutting conditions, which means that a significant change of gap width can develop depending on speed. NUMcut’s variable offset control (VOC) function automatically changes cutting path so the part’s final contour remains true to size despite the changing radius of the cutting jet, thereby maintaining the dimensional accuracy of each part.