Five Tools From Big Kaiser

The producer of high-precision tooling solutions introduces a drill for low cutting speeds, dual-purpose milling cutter, jet-through hydraulic chuck line for 5-axis machining, and new EWA fine boring heads and EWE digital boring heads.

Posted: October 21, 2020

BIG KAISER Precision Tooling (Hoffman Estates, IL) expands its product line with five specialized cutting and drilling tools.

Available in diameters from 0.30 mm to 3.00 mm, the Nirox high-performance drill from Sphinx was developed for use at low cutting speeds in unstable environments. The Nirox geometry has a degressive helix angle equal to 30 degrees at the point and is designed for accurate and precise hole location up to 9xD. TiAlSiN-based coating allows for enhanced chip and coolant evacuation in difficult-to-machine and adhesive materials such as titanium, Inconel, stainless steel, hardened steel, and CoCr alloys.

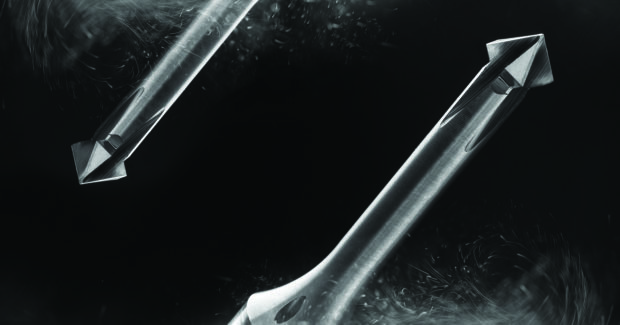

Chamfering the entry and exit of 0.80-mm-to-6.00-mm holes can be tedious and time-consuming. Ideal for 90-degree front and back chamfering and deburring holes up to 4xD, the geometry of the Noventa milling cutter from Sphinx improves cycle time, tool life, and surface quality. Similarly, finished holes and parts are often deburred using time-consuming, inefficient operations that lack repeatability. Noventa’s four flutes and four coolant channels optimizes performance and cycle time. Outstanding tool life in most common and exotic materials is achieved using modern double-layer coating techniques. This milling tool also provides great surface finish due to its reinforced shank diameter and edge-breaking capabilities, a critical final step to create a part that looks and feels like a finished product and is safe to handle.

The company expands its jet-through hydraulic chuck line to include the BCV interface and additional inch sizes. The HDC jet-through type holders are ideal for high-precision 5-axis machining with maximum RPM of 35,000 and clamping range of ¼-inch to ½-inch, and fit nearly any application in the automotive, aerospace, medical, and die and mold industries.

An exclusive thread allows for convertible coolant delivery between jet-through coolant and center-through coolant. Jet-through hydraulic chucks are ideal toolholders for finishing applications that would benefit from improved coolant delivery. The coolant flows through the end of the toolholder and is angled to direct coolant to the cutting tool tip, greatly improving surface finish and tool life.

Only one hex key wrench is needed to clamp or loosen the cutting tool, making tool changes fast and easy without special equipment. Every HDC toolholder is guaranteed to 0.00012-inch TIR at 5xD.

When used with in-process measuring, a closed-loop system featuring the intelligent EWA68 fine boring head lowers scrap volume, improves accuracy, and saves considerable time by automatically compensating for cutting edge wear. The head has a travel range of 0.866-inch on diameter and, with the smallest insert holder, covers the range of Ø2.677 to 3.543-inch. This means that similar-sized bores on the same part could be produced with a single boring head. Range can be extended to Ø5.197-inch by adding two larger insert holders.

Integration is accomplished via an external industrial PC to handle machine control communications and boring head adjustment; newer machine tool controls may be suited to handle the EWA software directly. Where in-process gaging isn’t present, the boring head is adjusted through manual data input into a tablet or mobile device.

Finally, BIG KAISER is expanding its line of EWE digital boring heads with sizes down to the CKB1 modular tooling connection size, which means boring down to Ø.787-inch for Series 310 peripheric heads and Ø.016-inch for Series 112 centric boring heads. To ensure an easy transition to digital tooling for all applications, the new heads have the same ranges and accept the same accessory products as their standard analog counterparts.

Due to their small size, adjustment value is shown via an app on a mobile device or tablet instead of on the head itself. Once connected to the head, the app also can be used to set the target diameter and tolerance. The information stays assigned to the head connected until the operator changes it. Along with the last measured cut information (entered by the operator each time an adjustment needs to be made), the app can show the adjustment required to get the head set to the target diameter.

An optional handheld device that simply displays the incremental adjustment value is also available for manufacturers that don’t permit personal mobile device use on the shop floor. Four push buttons ensure easy use – Enter/ON, Back/Disconnect/OFF, Scroll down (Tool Select, Metric/Inch), Display Reset – and there’s a battery level indicator.