Can You Separate Myth From Fact in Industrial Welding?

From rework and spatter to productivity and training, you might have numerous challenges you want to tackle in your manufacturing welding operation. Some common manufacturing myths may be holding you back from making the right changes — or even from knowing where improvements are needed.

Posted: October 5, 2020

WELDING TIPS COLUMN

BY JASON DUNAHOO

Are inefficiencies or rework in your welding cell dragging down productivity in your entire operation? If so, some common manufacturing myths may be holding you back from making the right changes — or even from knowing where improvements are needed. Whether your goal is to control spatter or to increase arc-on time, knowing the facts can help you make improvements.

Learn more about six common myths so you can separate fact from fiction and keep your welding operation ahead of the competition.

MYTH 1: My operators are welding 50% to 60% of the time.

FACT: Arc-on time averages 12% to 15% in most welding operations.

Many people overestimate arc-on time. Welders often spend their time on tasks that aren’t value-added for the operation, such as grinding spatter or replacing consumables. Operations may also consider activities like part fit-up and machine setup as part of the welding time figure. However, those tasks shouldn’t be included when tracking arc-on time.

Skilled welders are at a premium, so it’s important to keep them under the hood as much as possible.

You can’t improve what you don’t measure. Look for a welding information solution that provides valuable data and measures arc-on time in each weld cell, which operations can use to increase productivity and manage costs. This data provides visibility into where nonvalue-added activities can be shifted to other areas to free up welder time for welding.

MYTH 2: Grinding and chipping are part of the welding process and can’t be avoided.

FACT: Using proper parameters and machine setup can greatly reduce or eliminate spatter.

Stop thinking of grinding and rework as part of the welding process. These nonvalue-added activities cost a lot of time and money — and they can be avoided.

Taking the time to establish the proper weld parameters for the job can reduce or eliminate the time spent grinding and chipping to remove spatter. Training operators to use a shorter contact-tip-to-work distance can also help reduce spatter.

Deltaweld systems from Miller offer EZ-Set technology, which makes it simple for operators to choose the right parameters and minimize spatter.

MYTH 3: Pulsed MIG is slower than traditional MIG.

FACT: Pulsed MIG can provide faster travel speeds when proper procedures are used, boosting productivity.

The belief that pulsed MIG is slower than conventional MIG welding may hold some operations back from making the switch. But pulsed MIG can provide productivity boosts for most applications.

When average weld current is maintained, along with adjustments to arc length and travel speed to maintain similar bead size, pulsed MIG welding typically provides faster travel speeds with lower spatter compared to conventional MIG.

Deltaweld systems deliver pulsed capabilities in an integrated package and offer Accu-Pulse technology, which provides a 28% wider operating window and a more forgiving arc to help speed up the operation.

MYTH 4: Automation is too expensive to implement.

FACT: A wide range of automated welding solutions are available that benefit companies large and small.

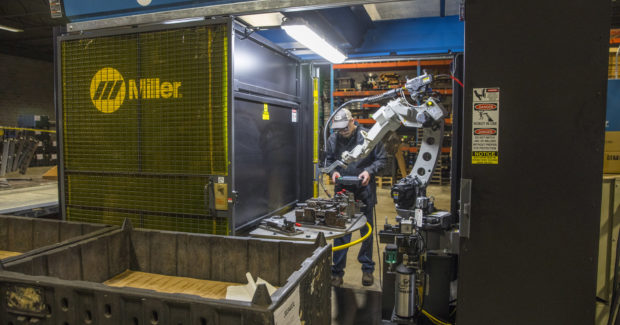

Large, customized automation cells provide benefits for many manufacturers, but they aren’t the right fit for everyone. Smaller, more nimble cells may be the answer for manufacturers that want to implement robotic welding. They’re easy to install and get running quickly and don’t require as much overhead or labor to keep running.

Look for robotic welding systems that come preassembled and prewired. Single power and air connections simplify the setup process, minimizing downtime so manufacturers can start using the system faster.

Another option is the emerging technology of collaborative robots, or cobots. A cobot shares the same space as and collaborates with a human welder. For example, a cobot can move parts into position while the human operator welds them together.

MYTH 5: It’s too expensive to train new welders in-house.

FACT: Training is faster and more affordable than ever with new technologies.

Many manufacturers struggle to find experienced welders. Some are launching in-house training programs to help fill this gap. They may train a dozen new hires at the same time before sending them to the production floor.

In-house training isn’t limited to large manufacturers. Affordable solutions are available that can help smaller companies save time and money in welder training.

Augmented reality welding systems simulate multiple welding processes, blending real-world and computer-generated images into a virtual educational environment. This lets new welders build their muscle memory and learn the basics of welding without using costly consumables or filler metal.

MYTH 6: It costs too much to track quality and productivity in each weld cell.

FACT: Payback can happen quickly with welding intelligence.

Investing in a welding intelligence system can provide data that helps reduce rework and cut costly downtime.

Insight Centerpoint arc data monitoring software from Miller can provide real-time operator feedback and guided work instructions. This prevents missed welds and enforces proper weld sequences to help ensure consistent quality.

When operations have complete traceability, they can trace defects back to their origins and adjust training or weld parameters to eliminate that defect.