Additive Manufacturing for Air, Land, Sea, and Space Applications

Sciaky’s wire-based electron beam additive manufacturing (EBAM) 3D printing technology is faster, less expensive, and safer than other direct energy deposition (DED) options. Closed-loop adaptive control system ensures precision and repeatability.

Posted: October 9, 2020

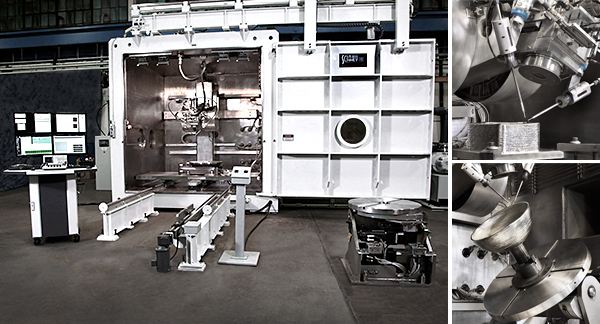

Electron beam (EB) welding and electron beam additive manufacturing (EBAM) equipment builder Sciaky Inc. (Chicago, IL) has experienced an uptick in business during the pandemic for research and development (R&D) projects as well as to produce prototype and production parts, mostly tied to the aerospace industry. Many involve high-value materials such as titanium, Inconel, niobium, copper-nickel, and stainless steel.

The company’s EBAM metal 3D printing solution is a wire-based direct energy deposition (DED) process. Wire feedstock/raw material is available in titanium, tantalum, tungsten, Inconel, niobium, nickel-copper/copper-nickel, aluminum, molybdenum, zircalloy, and stainless steel. In many cases, wire feedstock is 50% cheaper (or more) than powder feedstock. In addition, wire feedstock is safer and easier to store than powder feedstock (the powder used in aluminum and titanium is known to be highly flammable).

As the most widely scalable metal additive manufacturing solution in the industry (in terms of work envelope), Sciaky’s systems produce parts ranging from 8 inches (203 mm) to 19 feet (5.79 meters) long. EBAM is also the fastest deposition process, with gross deposition rates up to 25 pounds (11.34 kg) of metal per hour.

Sciaky’s interlayer real-time imaging and sensing system (IRISS) is the only adaptive control system that senses and digitally self-adjusts deposition with precision and repeatability. This closed-loop control is the primary reason the company’s printing process delivers consistent part geometry, mechanical properties, microstructure, and metal chemistry from the first part to the last.

Sciaky’s EBAM is the only industrial metal 3D printing solution with approved applications for land, sea, air, and space.