System Simplifies Robotic Mobile Quality Inspection

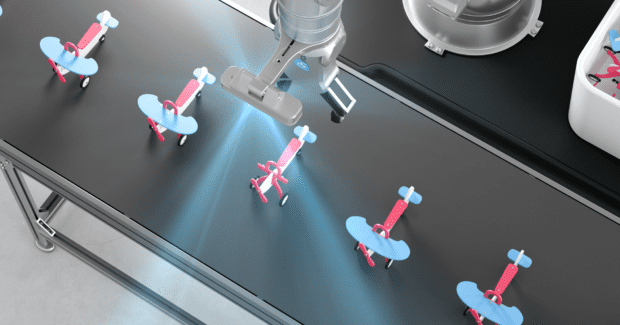

OnRobot’s updated Eyes robot vision system sorts, inspects, and picks-and-places parts using color and contour – what the company calls one-shot detection – instead of workpiece teaching, greatly reducing cycle times and easing the programming process.

Posted: September 30, 2020

OnRobot (Odense, Denmark) updates its 2.5D camera-based Eyes vision system. New features enable Eyes to be deployed in quality inspection applications and on mobile robots. They include one-shot detection for multiple objects, color, and blob detection as well as automatic Landmark calibration tools designed to speed mobile robot setups.

New visual inspection features reduce cycle time by enabling the system to easily sort, inspect, or pick-and-place unstructured objects using color and contour detection, a capability that’s beyond most competing vision systems. This detection method requires no workpiece teaching and finds items based on color and size information input by the operator.

Inspection features can be used to inspect parts removed from CNC machines, for example, or to check IMM parts for excessive or inadequate material after the part has been molded. The tools also support manual inspections: Operators can set up a camera and inspection program, manually place a workpiece, and execute inspection. No robot required.

The update provides one-shot detection for multiple objects, allowing the system to pick all workpieces with only one picture. This reduces complexity for users and improves cycle times. New tools allow users to request specific workpiece types and specify gripper clearance parameters.

With more manufacturers looking to deploy robot arms on mobile platforms for various production applications, a new Landmark feature enables easy deployment on mobile robots and setups with carts, trays, and pallets. Robots are programmed to move from station to station using user-defined Landmarks as their guide. Landmarks can also be used to initiate specific robot operations; for example, when Eyes detects the arrival of a loaded cart in its workspace, it can easily switch to pick-and-place routines.

“Traditional approaches to industrial automation place the product at the center, which results in costly, over-complicated solutions to simple automation problems,” says CEO Enrico Krog Iversen. “We take a more practical approach. This means giving customers easy-to-use tools tailored to specific application needs and empowering them through updates to existing products that enable deployments in new applications.”