Safe, Ergonomic Unpacking Of Sheet Metal Stacks

KASTO’s plate handler significantly reduces the amount of manual labor involved in unpacking and storing heavy plates. The machine also provides processors of sheet metal an attractive way to automate storage of heavy sheet metal stacks.

Posted: September 24, 2020

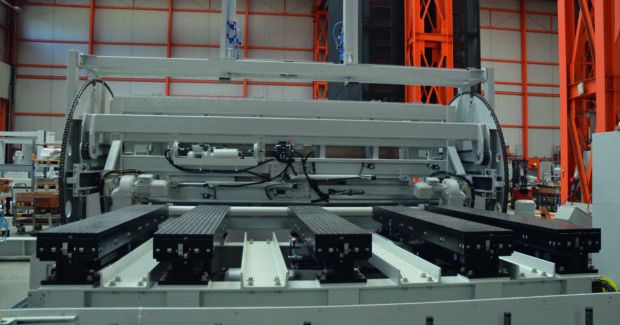

Suitable for sheet metal stacks in formats MF, GF and XF with weights up to 5 metric tons, the plate handler from KASTO Maschinenbau GmbH & Co. KG (Achern, Germany) offers sheet metal distributors and processors an economical means of automating the laborious process of unpacking and storing. It can also handle diamond plates and set them down on either side as needed.

The plate handler consists of a drum-shaped turning device with a support table that can be raised and lowered. A stack of sheet metal is placed by a forklift before it’s unpacked. The stack is positioned in the center, ensuring a very stable setup. The operator removes the straps, sheeting and edge protectors from the top side. The drum then rotates 180 degrees, allowing for easy removal of the remaining packaging and the wooden pallet. Following this, the plate handler returns to its starting position.

After the packaging has been removed, vertical and horizontal guides align the plates according to the operator’s requirements: centered or at a reference corner. Telescopic forks then convey the plates to a waiting cart and onto a storage pallet. In this way, the user is prepared for automated storage and processing without any heavy lifting or carrying. The result is greater efficiency and better workplace ergonomics while avoiding accidents and injuries.

The machine seamlessly connects to all Kasto sheet metal storage systems, ensuring a consistent, efficient, and ergonomic material flow.