Rough and Finish with One Tool

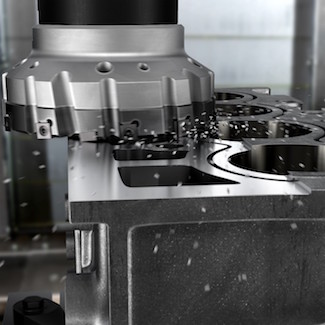

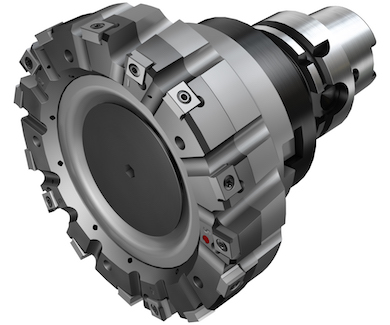

Sandvik Coromant’s M5C90 milling cutter resolves the challenges of machining lightweight aluminium by roughing and finishing in one pass cylinder heads, cylinder blocks, and other automotive components formerly made from heavier cast iron alloys.

Posted: August 26, 2020

Roughing and finishing critical and complex automotive components from cast iron is an expensive and time-consuming process requiring multiple tools, which means two setups and more coolant to reduce the heat from heightened friction levels. Aluminum is lighter but also much softer, so poor-quality finishes, burring, and irregular tool wear are common.

Sandvik Coromant’s (Fair Lawn, NJ) M5C90 is designed for the roughing and finishing face milling of cylinder heads, cylinder blocks, and all-aluminum parts within wide cutter engagements (not applicable on thin-wall parts). The aluminum cutter performs rough and finish milling in one pass and, in many cases, at up to 6 mm in axial depth. The company reports five times longer tool life with a 200% cycle time reduction.

A series of precise and long-lasting polycrystalline diamond (PCD) tips is arranged in a circular configuration to progressively remove a bit more material from the workpiece both axially and radially. The tool’s final tooth is a wiper design that provides superior finish and flatness. The fixed position of the wiper and the teeth also eliminates complex and time-consuming pre-setting procedures.

While several tools are required to completely finish an automotive aluminum component, this tool removes much of the strain the material faces during machining.