Part Deburring, Cleaning, and Drying On A 15-Second Cycle

Combining high-pressure water jet deburring with low-pressure part cleaning and drying processes, the EcoCvelox from Ecoclean Inc. is a one-stop finishing solution. Highly configurable equipment enables highly flexible process design.

Posted: August 25, 2020

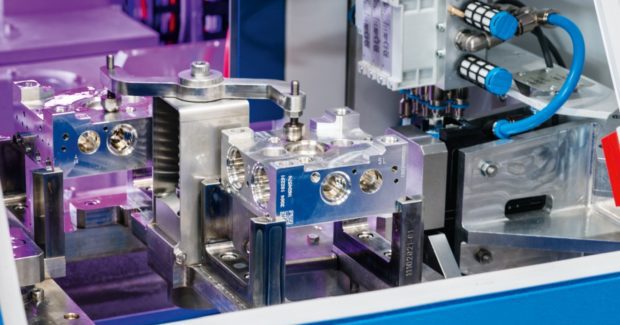

Hydraulic and pneumatic system components, small engine blocks, pump and valve housings, nozzles, transmission parts, steering and brake elements – these are just parts subject to increasingly stringent specifications for deburring and technical cleanliness. Meeting these requirements used to involve multiple pieces of equipment from different manufacturers, but the modular EcoCvelox from Ecoclean Inc. (Southfield, MI) is a one-stop solution that enables manufacturers to configure an easily expandable system combining deburring, cleaning, and/or drying of parts measuring 200 mm x 200 mm x 200 mm.

Deburring is performed by the standard single spindle at 1,000 bar pressure (maximum 3,000 bar) or optional HP turret that changes up to five tools in 1.5 seconds. The tools for either can be custom-designed to match a part and manufactured via 3D printing.

For part cleaning, the processes of injection flood washing, spray cleaning, and selective rinsing are available and can be combined. Drying can be achieved by high-velocity air blow-off and/or vacuum, with the air-blowing solution integrated into the cleaning module. To avoid exhaust air, the system can be equipped with an energy-efficient recirculation system.

Part handling for deburring takes place in one Y-axis in the system’s basic version. However, for high throughputs and the associated cycle time requirements, the module can be fitted with a second Y-axis for simultaneous loading and unloading while deburring for an overall 15-second cycle time. The same can be achieved for the cleaning and drying module by integrating a second, concurrently operating work chamber.

Pallets are moved between stations via a linear drive system that conveys parts from one station to the next at 4 to 5 meters per second. Loading can be manual or automated via a gantry system or robot.

Patented software and a VFD-controlled high-pressure pump automatically readjust pressure to compensate for pressure drop as tools wear, extending tool life by at least 50% while boosting overall equipment availability.

A CAD/CAM interface transfers part design data for programming the deburring process. This can be done offline, which is easier and faster than any conventional teach-in method. This capability also helps to set up deburring of new parts in minimum time and at low cost. A camera system can be integrated for part identification.

An intuitive operator guidance system increases uptime by facilitating troubleshooting and response. Like a smartphone display, all modules appear in an overview diagram on a 19-inch monitor and, if a problem occurs, the affected module’s color changes to a shade of yellow or red. The operator touches the module’s icon to access a process technology diagram, flow diagram, or electrical circuit diagram that highlights the malfunctioning component. Another tap provides a more-detailed view and access to functions such as activate or deactivate. Lists of wear parts and spare parts in the digital documentation facilitate part ordering.