Advanced-Grain Nonwoven Belt Improves Stainless Steel Finishing Process

Finding people who are willing and able to press metal against an abrasive belt all day long can be challenging. Nonwoven belts make the job more appealing by increasing productivity without increasing effort.

Posted: August 12, 2020

SURFACE CONDITIONING COLUMN

BY MIKE D. SHAPPELL

Along with an increase over the past few years in stamping parts from stainless steel sheet, there’s been an increase in demand for qualified, skilled personnel to do the required hand finishing.

They’re not easy to find. The operation’s physical aspects are surely part of the challenge. Finding someone who’s willing and able to press metal against an abrasive belt all day long is difficult, so manufacturers should consider anything that reduces fatigue by facilitating the process.

Using a nonwoven abrasive belt can make hiring and retaining finishers easier.

Fabricating for the Food Industry

We recently did some testing at a high-quality manufacturing operation that fabricates components for the food industry from #430 stainless steel sheets. As with many manufacturers in that industry, the company’s goal is to achieve a #4-type finish after components are bent, formed, and welded into shape.

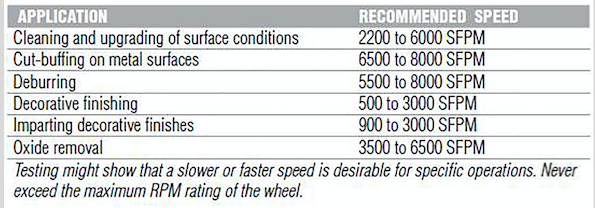

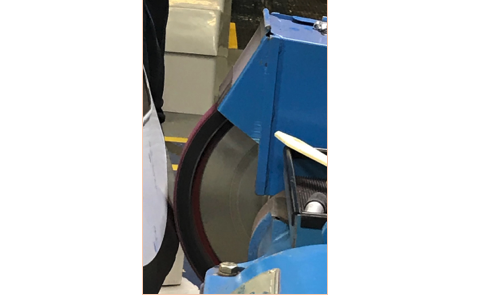

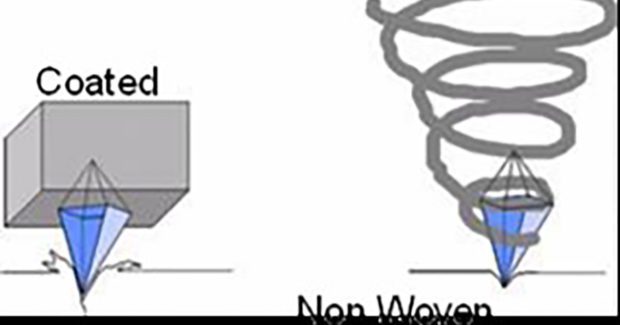

The company’s process involved using a standard-duty, nonwoven, medium-grade belt on a plain-faced rubber contact wheel in the 50-durometer range. The operation’s standard speed was 1,530 RPM on a 14-inch (outer diameter) wheel; a surface feet per minute (SFPM) rate of 5,600 was used to obtain a nice, structured finish.

We started our assessment by determining surface-finishing challenges. The manufacturer was concerned about the value of the current belt, but we wanted to evaluate the entire process because operators believed they were pressing harder against workpieces than they had in the past.

As our assessment progressed, we identified a couple things that could be adjusted to give them some relief.

Hard, Easier, Easiest (and Faster, Too)

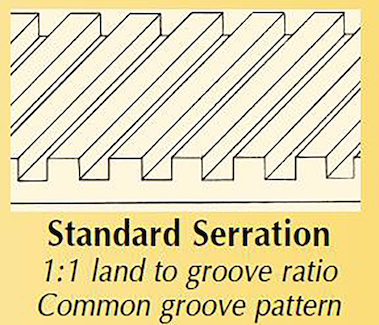

First, we asked the company to use a standard rubber 1:1 serration contact wheel instead of a plain-faced contact wheel. This immediately increased the cutting rate.

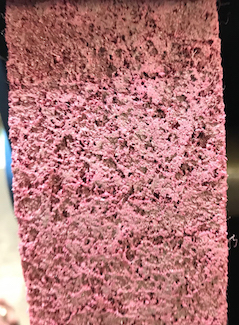

We ran many parts with this contact wheel modification using a standard Norton Rapid Prep medium-grade nonwoven belt. Our results were good, with operators achieving an acceptable finish despite applying less pressure.

The next step, after making sure all quality standards were being met, was to replace the standard Rapid Prep belt with the Norton Vortex Rapid Prep belt. While still in the medium-grit category, the Vortex friable grain provides a sharper cutting surface than standard aluminum oxide (A/O) grains.

As a result, operators were able to meet surface requirements using even less pressure. In addition, workpieces could be processed slightly faster because operators didn’t have to go over the same area multiple times.

While I’m a huge proponent of automating surface finishing whenever possible, our industry needs to advance abrasives technologies to optimize hand finishing. How something feels to the operator is important. An operation that requires extra effort can detrimentally impact output and/or cause repetitive motion injuries over time.

With the cut rate of the Vortex Rapid Prep belt, the operator will extend the life of the belt and reduce many belt changeovers per day. This will allow the operator to produce 5% to 10% more product in the same time frame – all while applying less part-to-abrasive pressure.

Upgrading to a Norton Vortex grain could be the answer to avoiding negative outcomes.